You can do the same to switches too, like your headlight or wiper switch. They don't use contact points, but they have connections that get oxidized and dirty.

If your not confident to do this, contact me, you pay shipping, and I will do it for free.

Clean the contact points on your factory relays (headlights, horn, voltage regulator, etc) it's just like the contact points in your distributor. The points get burnt, dirty, and oxidation accumulates on the copper ground straps. Doing this will usually will bring a dead relay back to life.

Here's the headlight relay from my 620; I did the same to the relays on my 510. The 510 high-beams wouldn't work; I did this and they worked again.

Bend the 4 tabs holding the metal cover on, and separate the bottom from the cover:

Cover off:

Remove the screw holding the copper plate on, so you can clean the copper surface. Brass wire brush, or 0000 steel wool works well.

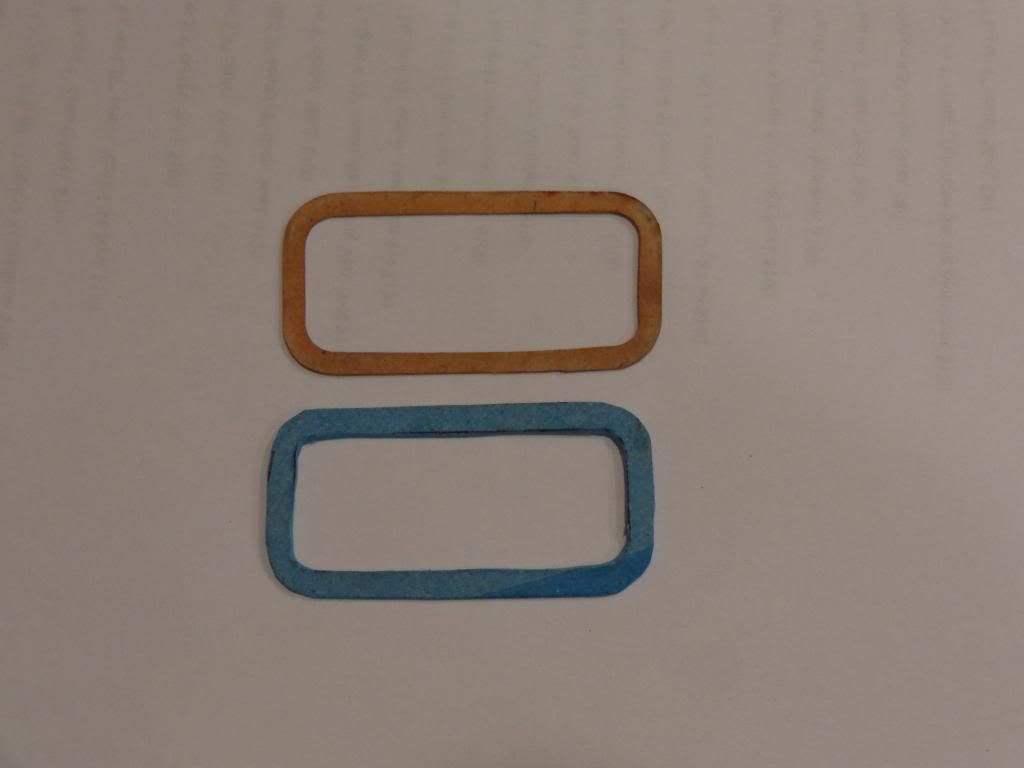

**Pictured are two versions of the screw/nut holding the copper plate on. ***Be careful not to break the wires... Yes they can be re-soldered if they break.

OR

Contact Points: Use Emory cloth to clean/smooth them (Local parts store usually has Emory cloth in the sheet, or roll)

Cleaning the points with Emory cloth. Make sure to spray the points and other connections with some "Electronics Cleaner" when finished, to remove any sanding dust.

I used some needle nose pliers to tweak the points a bit so they made better contact:

Don't forget the connector terminals:

I quickly cleaned the cover and made a new gasket for it:

Don't forget to clean any and all terminals, especially the forgotten ground terminals. This includes making sure the screw holding the terminal on, and the surface the terminal touches has clean bare metal touching all contact surfaces. Cover the connection with dielectric grease to keep moisture and corrosion out of the connection.