Fuck The Reaper

- 510freak

- Global Moderator

- Posts: 9706

- Joined: Wed Jun 26, 2013 6:44 pm

- Title: DJ Jazzy Lou

- Cars: Boo no 510 lol

- Location: Van Isle

- Has thanked: 6 times

- Been thanked: 7 times

- Contact:

Re: Fuck The Reaper

Nice!

Lots of little things add up to one very cool project done in the end

Lots of little things add up to one very cool project done in the end

Taterhead » Tue Dec 08, 2015 6:35 am wrote:[quote="Taterhead » Mon Dec 07, 2015 2:41 pm

Sorry, I was channeling my inner flatcat.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Done for the night and was going to updated. Photobucket said no. I'll try again in the morning.

When the only tool you have is a hammer every problem starts to look like a hippy.

- izzo

- Site Admin

- Posts: 5651

- Joined: Wed Jun 26, 2013 6:32 pm

- Title: Save a pimp, Rent a bitch.

- Cars: Too many

- Location: Astoria, OR

- Contact:

Re: Fuck The Reaper

fucking photobucket!

8========D ~~~ ( o Y o )

jayden71: titty ponk

devilsbullet wrote: 1400 obo. and best offer doesn't mean 300 bucks you cheap bastards

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

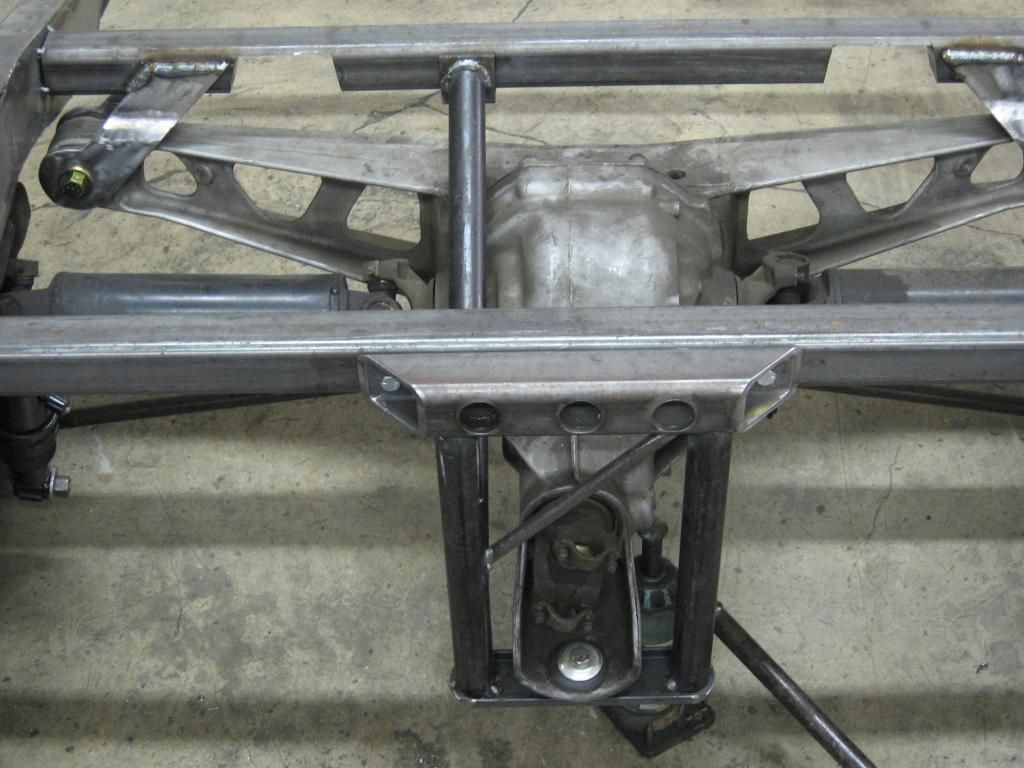

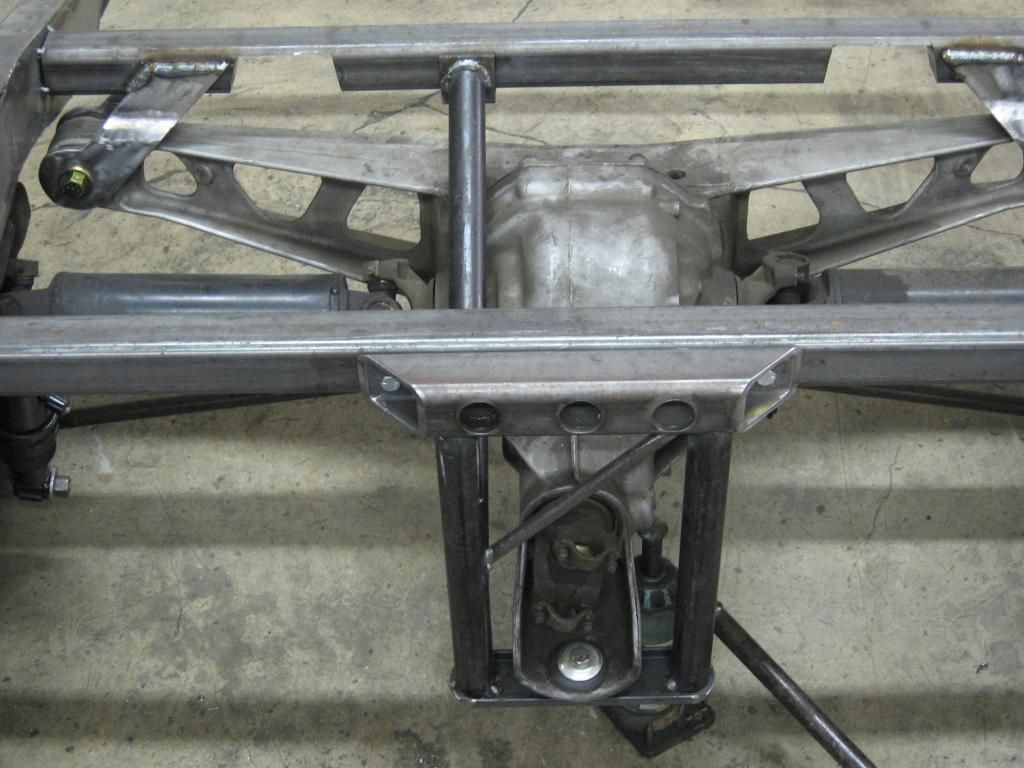

So, here is the progression of the trailing arm brackets. Welded the angle and flat portions together and ground down the external welds. Then bolted them together. This shows the adjustability of the slots.

Shock mounts...

Slight bend...

The hole in the top is for a rosette weld.

Got itchy and burned in a couple welds. I hope I don't end up regretting that.

This view is from above looking down between the frame rail and wheel/tire. As you can see the E-brake cable contacts the wheel. Just barely, but still needs to be dealt with.

Pulled the wheel and nipped it off. I'll weld it to the top of the trailing arm later.

Shock mounts...

Slight bend...

The hole in the top is for a rosette weld.

Got itchy and burned in a couple welds. I hope I don't end up regretting that.

This view is from above looking down between the frame rail and wheel/tire. As you can see the E-brake cable contacts the wheel. Just barely, but still needs to be dealt with.

Pulled the wheel and nipped it off. I'll weld it to the top of the trailing arm later.

When the only tool you have is a hammer every problem starts to look like a hippy.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Back to the trailing arm brackets...

Bolted in place to check where to trim.

At this point I needed to check my alignment to see how to notch it. The method I used was to clamp some square tube near the front of the frame. I established my centerline then measured out each way to match the outside width to the rear tires.

Another square tube used as a straight line.

Then I could roughly square up the rear tires.

I initially thought I would cut a U shaped pocket that would saddle the frame from the bottom. Once I got the rear alignment roughed in it was clear that it the trailing arms were going to be mounted more outboard than centered with the rails.

This is what I ended up with.

I won't weld them on to the frame until my adjustable strut rods show up. Hopefully by next weekend.

Forgot to show the end product front mount. I added a diagonal support and one fore/aft. Not sure they are needed but better to have them than wish I did. Triangles are strong.

Bolted in place to check where to trim.

At this point I needed to check my alignment to see how to notch it. The method I used was to clamp some square tube near the front of the frame. I established my centerline then measured out each way to match the outside width to the rear tires.

Another square tube used as a straight line.

Then I could roughly square up the rear tires.

I initially thought I would cut a U shaped pocket that would saddle the frame from the bottom. Once I got the rear alignment roughed in it was clear that it the trailing arms were going to be mounted more outboard than centered with the rails.

This is what I ended up with.

I won't weld them on to the frame until my adjustable strut rods show up. Hopefully by next weekend.

Forgot to show the end product front mount. I added a diagonal support and one fore/aft. Not sure they are needed but better to have them than wish I did. Triangles are strong.

When the only tool you have is a hammer every problem starts to look like a hippy.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Moving up to the front, I broke everything back down. The installation instructions call for a 1* tilt back on the front crossmember. Since I wasn't sure what my ride height was going to be when I tacked it in, I ended up with 3-4* once everything was leveled. Not horrible but I decided to slice it back out and redo it.

Bolted it back together but left off the rotors and calipers so I could use actual wheels and tires.

At the end of the night my brother showed up. I took a bunch of measurements from his pickup to compare with mine. Looks like mine will have a much narrower (about 4") track width than his so wide tires and offset wheels won't be an issue. I'll probably be about 4 inches lower in the front and 1 inch in the rear if I leave it all where it is. So now I need to mock up the body and see what it looks like before I do any more permanent welding.

Bolted it back together but left off the rotors and calipers so I could use actual wheels and tires.

At the end of the night my brother showed up. I took a bunch of measurements from his pickup to compare with mine. Looks like mine will have a much narrower (about 4") track width than his so wide tires and offset wheels won't be an issue. I'll probably be about 4 inches lower in the front and 1 inch in the rear if I leave it all where it is. So now I need to mock up the body and see what it looks like before I do any more permanent welding.

When the only tool you have is a hammer every problem starts to look like a hippy.

- izzo

- Site Admin

- Posts: 5651

- Joined: Wed Jun 26, 2013 6:32 pm

- Title: Save a pimp, Rent a bitch.

- Cars: Too many

- Location: Astoria, OR

- Contact:

Re: Fuck The Reaper

Sweet mother of progress.

How much does a ticket to stare in your window while you do this cost?

How much does a ticket to stare in your window while you do this cost?

8========D ~~~ ( o Y o )

jayden71: titty ponk

devilsbullet wrote: 1400 obo. and best offer doesn't mean 300 bucks you cheap bastards

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

It's super boring and the compound has no windows. But I appreciate your enthusiasm.

When the only tool you have is a hammer every problem starts to look like a hippy.

- izzo

- Site Admin

- Posts: 5651

- Joined: Wed Jun 26, 2013 6:32 pm

- Title: Save a pimp, Rent a bitch.

- Cars: Too many

- Location: Astoria, OR

- Contact:

Re: Fuck The Reaper

lol.

Coming along nicely dude. Keeps getting better every post. Welds look good too. Love metal work, just never knew what to make. Need to just get out and do it. But wtf would i even build

Coming along nicely dude. Keeps getting better every post. Welds look good too. Love metal work, just never knew what to make. Need to just get out and do it. But wtf would i even build

8========D ~~~ ( o Y o )

jayden71: titty ponk

devilsbullet wrote: 1400 obo. and best offer doesn't mean 300 bucks you cheap bastards

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Thanks, guys.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Fuck The Reaper

Great work being done here, keep it up and you will get done one day, but then what will you do?

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Thanks Wayno. There's already a growing list for after this is done.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Fuck The Reaper

But they are never done

DRIVEN » Mon Oct 27, 2014 7:55 pm wrote:Thanks Wayno. There's already a growing list for after this is done.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Mailman brought me some shinys!

...and since it was a slow day at work I cleaned up my front rotors and resurfaced them.

...and since it was a slow day at work I cleaned up my front rotors and resurfaced them.

When the only tool you have is a hammer every problem starts to look like a hippy.

- izzo

- Site Admin

- Posts: 5651

- Joined: Wed Jun 26, 2013 6:32 pm

- Title: Save a pimp, Rent a bitch.

- Cars: Too many

- Location: Astoria, OR

- Contact:

Re: Fuck The Reaper

Mmm fresh rotors!!

Man I love new parts. I can't have none right now, so I am oogling yours.

Man I love new parts. I can't have none right now, so I am oogling yours.

8========D ~~~ ( o Y o )

jayden71: titty ponk

devilsbullet wrote: 1400 obo. and best offer doesn't mean 300 bucks you cheap bastards

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

My brother actually started working on the passenger door. Haven't seen or heard from him in almost a week. Hope this isn't a false start.

When the only tool you have is a hammer every problem starts to look like a hippy.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

Today's progress...

Starting with the strut rods; As you can see, there is a pretty good angle on the rod ends. Turns out there was more than I needed once things were in place. They still technically fit but the bushings were a little more stressed than necessary. That gave me an excuse to drag out the new torch set and try it out. Well, the Acetylene regulator leaks but it still worked fine. Anyway, I took about half the angle out of all 4 ends. Then painted everything up before reinstalling them.

Next up was to align the rearend and tack the trailing arm brackets in place. Gussets and bracing will be added once I'm sure everything is in it's proper place.

All done and aligned...

The spring will be installed and ride height adjusted once the weight of the body is on the chassis.

I didn't really take any close shots of the upper coilover mounts but they are tacked in and the temporary braces are in place. Couldn't resist rolling it outside to get a better walk-around look.

I got stalled out on the steering until I get some tie rod ends so I just moved back to the engine. Chucked up the oil pump primer and ran it until the rockers were wet. Also pulled out a few distributors and need to test them all and pick one.

Starting with the strut rods; As you can see, there is a pretty good angle on the rod ends. Turns out there was more than I needed once things were in place. They still technically fit but the bushings were a little more stressed than necessary. That gave me an excuse to drag out the new torch set and try it out. Well, the Acetylene regulator leaks but it still worked fine. Anyway, I took about half the angle out of all 4 ends. Then painted everything up before reinstalling them.

Next up was to align the rearend and tack the trailing arm brackets in place. Gussets and bracing will be added once I'm sure everything is in it's proper place.

All done and aligned...

The spring will be installed and ride height adjusted once the weight of the body is on the chassis.

I didn't really take any close shots of the upper coilover mounts but they are tacked in and the temporary braces are in place. Couldn't resist rolling it outside to get a better walk-around look.

I got stalled out on the steering until I get some tie rod ends so I just moved back to the engine. Chucked up the oil pump primer and ran it until the rockers were wet. Also pulled out a few distributors and need to test them all and pick one.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Fuck The Reaper

Progress is being made, good job, it looks good.

I didn't know one could straighten out a rod end.

I didn't know one could straighten out a rod end.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Fuck The Reaper

They were about 8* on each end. I took them to about 3*. Tough to tell the difference in the pics but it seemed to be just enough.

I can't wait to get this thing done.

I can't wait to get this thing done.

When the only tool you have is a hammer every problem starts to look like a hippy.