As promised...some pics...finally.

Dropped the cab and moved it in to the corner.

There were some gaps on both sides where the crossmember meets the frame rails. I used some scrap round stock to fill the gap. Then welded it all together.

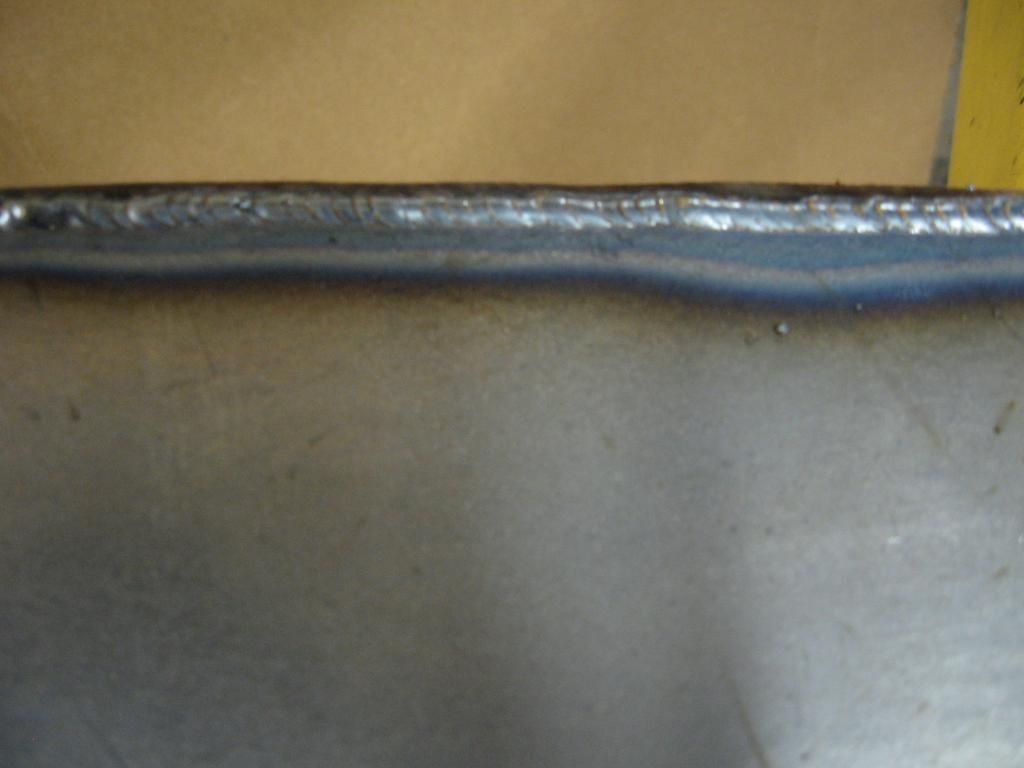

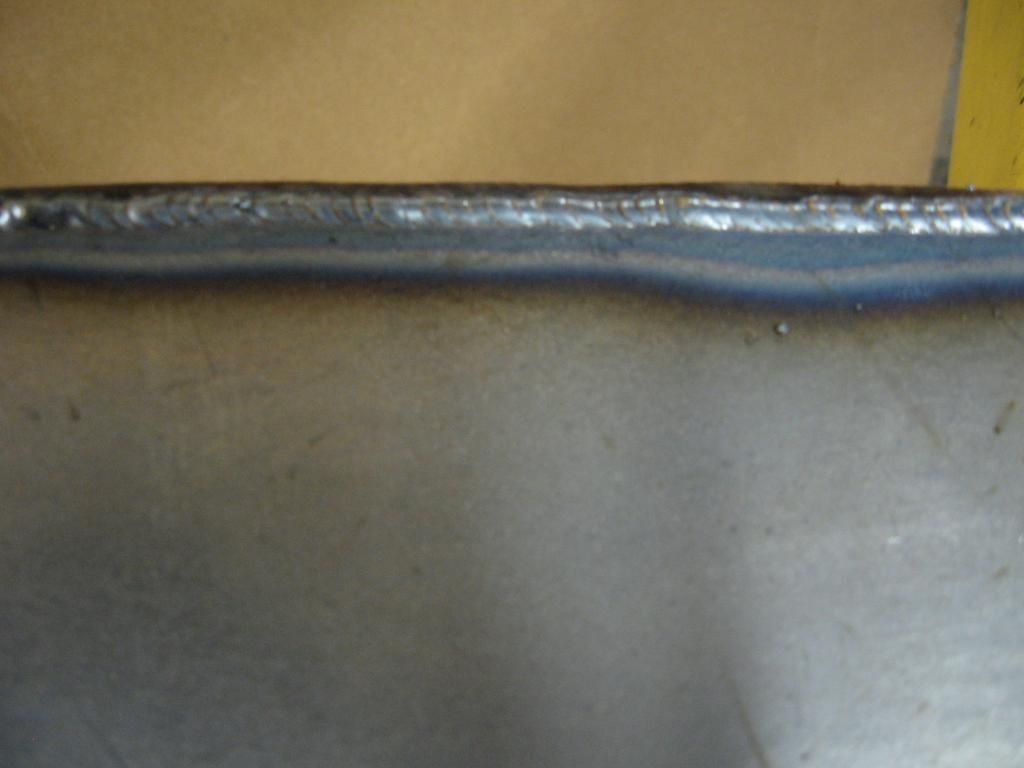

Since the cutout for the rack had been opened up after the crossmember relocation, I filled it back in. Then I Cut them out again, welded in the filler cuffs and did the cleanup grinding. What you can't see is the 1" solid stock bars that were welded to the inside of the frame rail to add a bit more frame strength. If it weren't for the swaybar mounts being ahead of the notches it probably wouldn't be necessary at all. I'm so embarrassed of these welds.

Another small point that needed attention was the transmission crossmember. For whatever reason, the manufacturer felt that a 3/16" flat plate would be sufficient. It was bowing just during the mockup. I added a 1"x1/4" strip to the front edge. Should be stiff enough now.

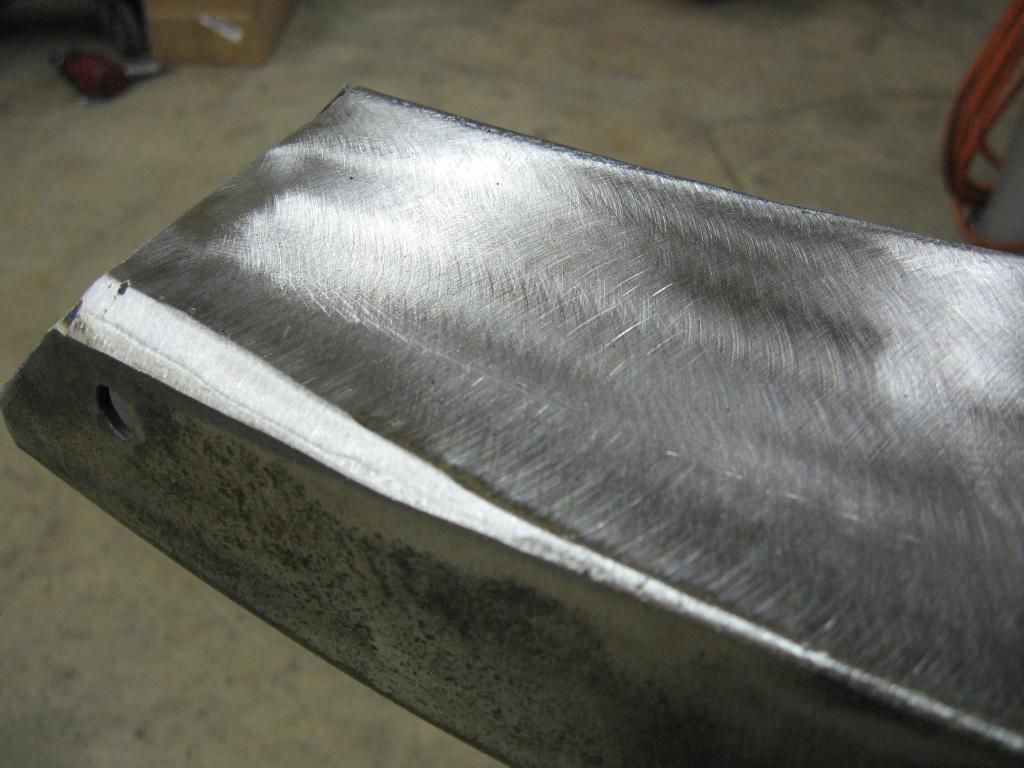

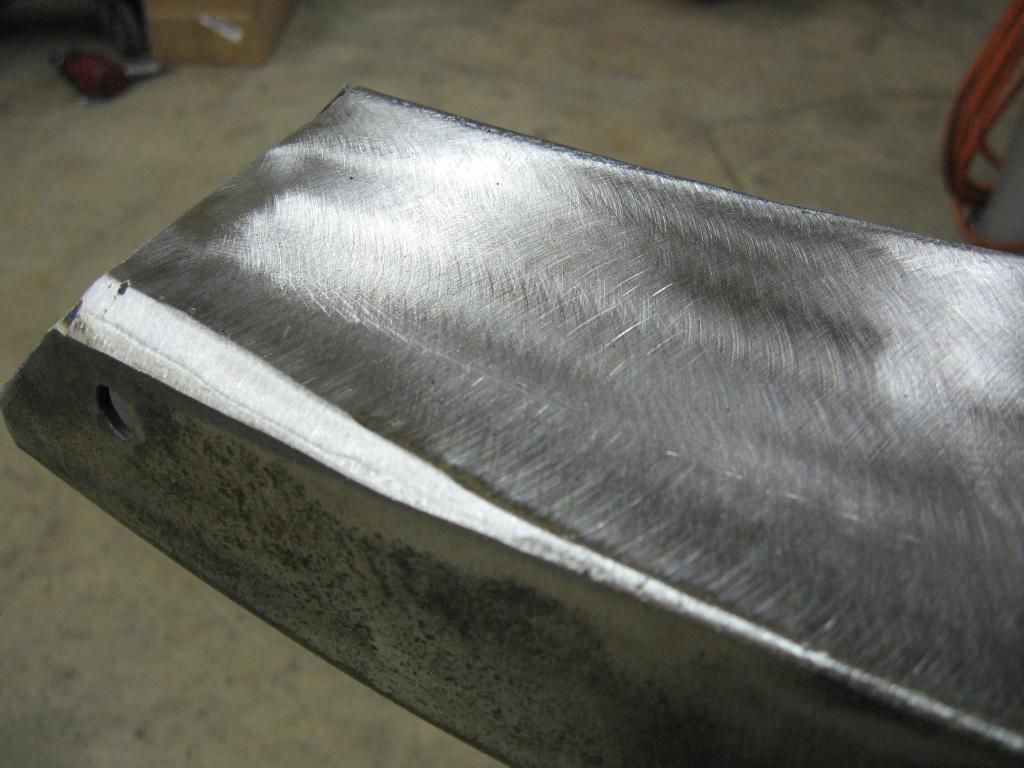

Then I got busy welding the boxing plates to the frame, grinding the welds smooth, hit the surfaces with a flapper disc.

At the very front the upper part of the rail angles in and the bottom stays straight. Since the angles didn't meet, I had to make a filler. Nothing fancy but little jobs like that take time. Several little jobs add up to days of work.

Tried to get a shot of the welds but camera did not want to focus. Basically, it's about 10000 continuous spot welds. Urg.

And there it is. Doesn't look much different does it?

When the only tool you have is a hammer every problem starts to look like a hippy.