Page 12 of 19

Re: Fuck The Reaper

Posted: Tue Jan 27, 2015 8:55 pm

by wayno

DRIVEN » Tue Jan 27, 2015 9:13 pm wrote:Truer words were never spoken.

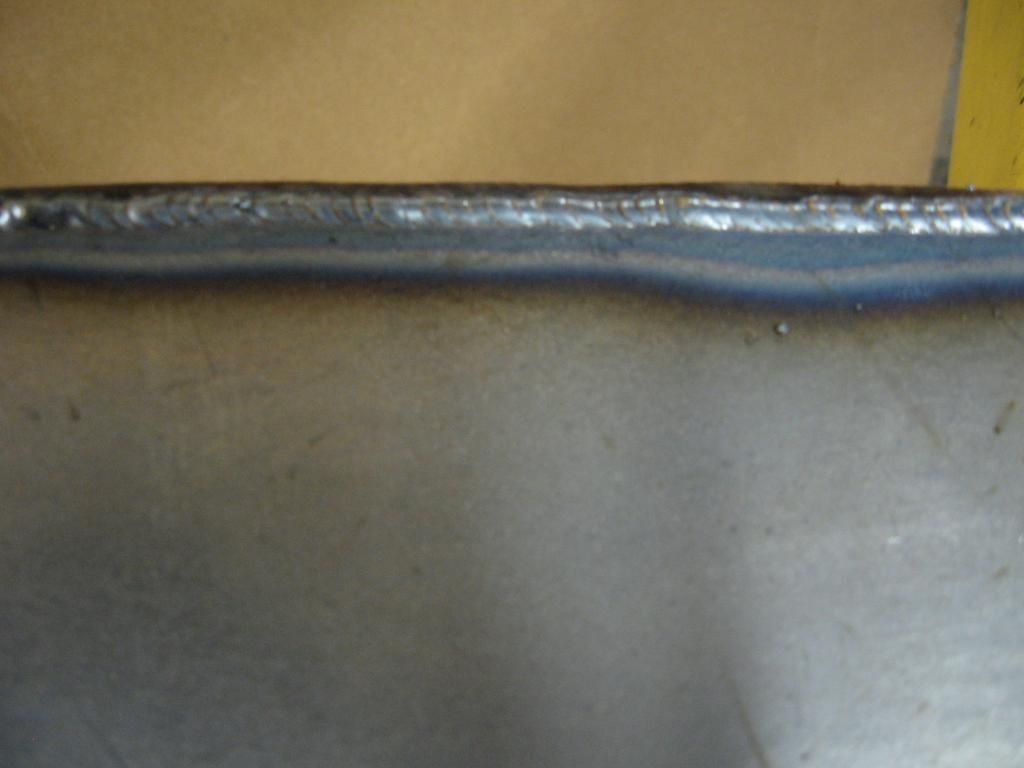

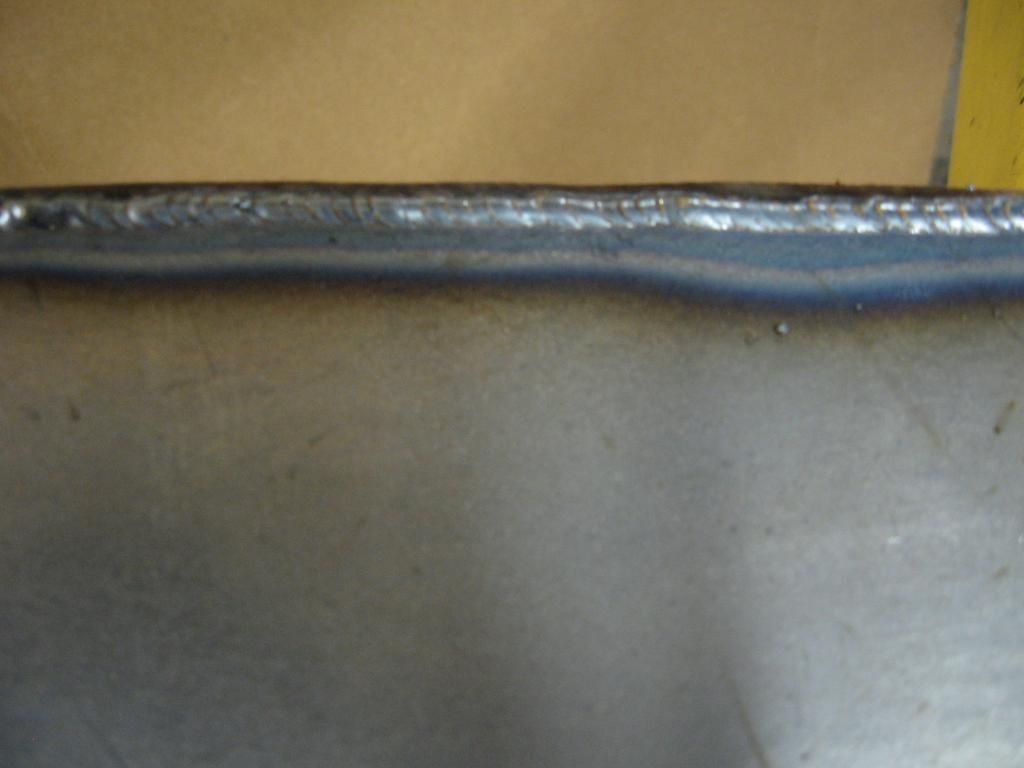

Honestly, I can lay a decent bead most of the time. Just having a hell of a time on this old Henry steel. Must be the 80 years of rust and contamination...or I might just be a shitty welder.

If it has pits of rust in it, it's not going to be pretty, as that is contamination, and that makes welding a lot harder.

Re: Fuck The Reaper

Posted: Wed Jan 28, 2015 6:59 am

by DRIVEN

I'm sure that's part of the problem. Every so often I'll get these weird growths in my welds. Like those little snake things you can buy around the 4th of July. I can grind them down easy enough but they are pretty porous. It'll be fine once it's all ground down and cleaned up. Strength is my primary concern anyway. This frame will be waaay stiffer than the original production version. Ford actually marketed these because of their ability to flex. That is not my goal at all.

Re: Fuck The Reaper

Posted: Wed Jan 28, 2015 7:06 am

by DRIVEN

Just spent the last 45 minutes searching for a marketing photo from the mid '30s showing a Ford with the 2 rear wheels and one front on the ground while the other front is up on a keg/drum. I've seen it a few times over the years but can't find it now. Part of the flexamatic action is thanks to the front and rear transverse leafs with no sway bars and the other was just due to the fact that the frames were flexible. When I lived in Pendleton there was a set of RR tracks that ran diagonally across the road at the end of town. If I hit them at the right speed, the passenger door would pop open. And that's even with the cab being spring mounted to the frame from the factory.

Re: Fuck The Reaper

Posted: Wed Jan 28, 2015 1:01 pm

by izzo

Not a keg, but shows the flex. Saw a model T on craigslist the other day with a clear shot of the rear leaf & axle and thought exactly that, thing probably flexes awesome. Tho back then you probably had to make sure your load was level or it'd lean like a mofo.

Re: Fuck The Reaper

Posted: Thu Jan 29, 2015 10:42 am

by K_trip

DRIVEN wrote:Part of the flexamatic action is thanks to the front and rear transverse leafs with no sway bars and the other was just due to the fact that the frames were flexible.

My Dad got me into Model T's at an early age, they are very cool cars. When they were a modern car there wasn't much in the way of paved roads. These cars would do circles around some of the crazy "off road" vehicles today (eg: 2015 Ford Explorer). High ground clearance, light and flexible, geared low - they're great cars.

You can see my

1926 Four Door Model T in my garage, behind a pile of broken Datsun parts.

Sorry to high-jack this

... but it's easy to get me going when it comes to Model T's

Re: Fuck The Reaper

Posted: Thu Jan 29, 2015 7:41 pm

by DRIVEN

Very cool! A bit of a coincidence to tie our projects together; When I got this truck it had a flathead in it. Not sure if it was the flathead that came in it but it was correct for the truck. PO had put a cam in it and shaved the heads. I later found out it had some crack repairs done to the block from being over heated. How did I find out? Started running warm and I thought I was losing a head gasket. That's when I found the "repairs". I found another flathead and ran it for a year or so and started collecting parts for a SBC swap. I came up with a belhousing adapter, flywheel, clutch, etc. I was hoping to find a 265 for nostalgic purposes but my dad located a 283. It's previous home -- a '26 T.

Re: Fuck The Reaper

Posted: Thu Jan 29, 2015 8:02 pm

by 510freak

All this Model T talk,have to get a pic of my dads 26 stocker.

Re: Fuck The Reaper

Posted: Fri Jan 30, 2015 2:03 pm

by K_trip

DRIVEN wrote:It's previous home -- a '26 T.

Nice

510freak wrote:All this Model T talk,have to get a pic of my dads 26 stocker.

+1

Re: Fuck The Reaper

Posted: Sun Feb 01, 2015 7:47 pm

by DRIVEN

As promised...some pics...finally.

Dropped the cab and moved it in to the corner.

There were some gaps on both sides where the crossmember meets the frame rails. I used some scrap round stock to fill the gap. Then welded it all together.

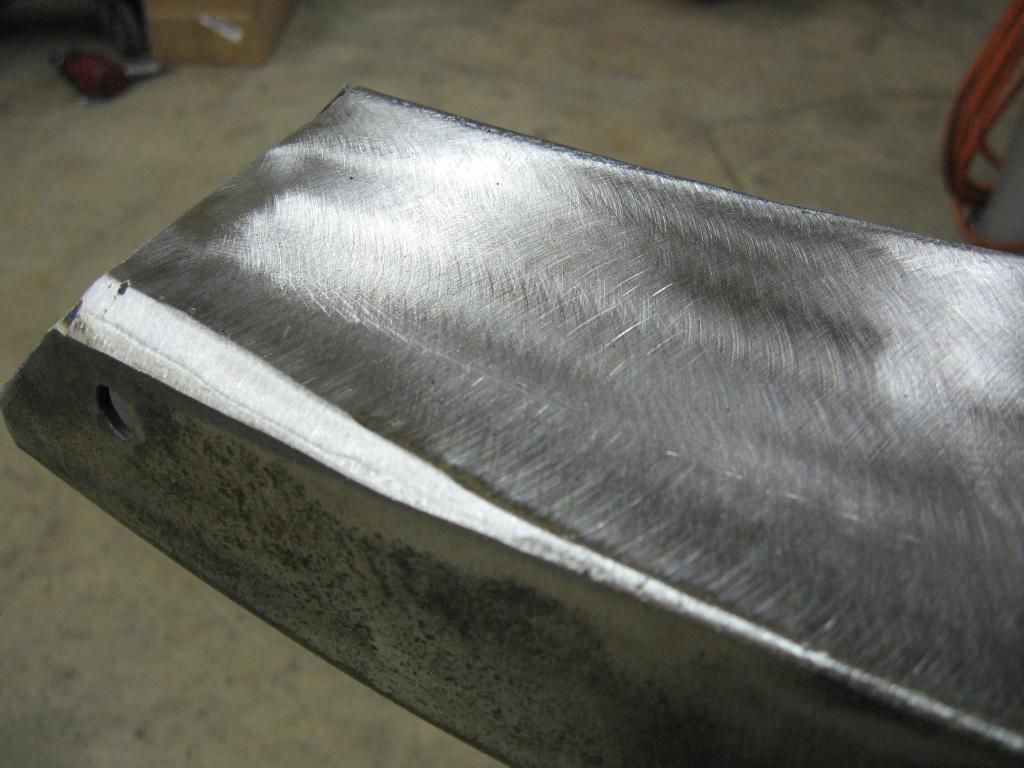

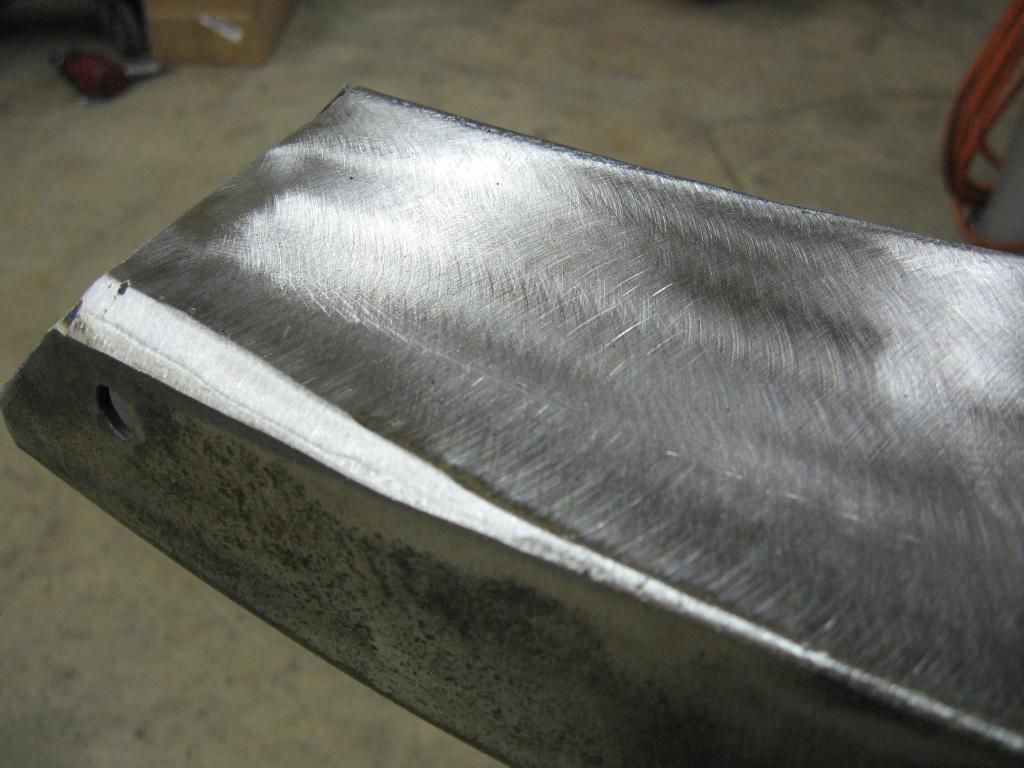

Since the cutout for the rack had been opened up after the crossmember relocation, I filled it back in. Then I Cut them out again, welded in the filler cuffs and did the cleanup grinding. What you can't see is the 1" solid stock bars that were welded to the inside of the frame rail to add a bit more frame strength. If it weren't for the swaybar mounts being ahead of the notches it probably wouldn't be necessary at all. I'm so embarrassed of these welds.

Another small point that needed attention was the transmission crossmember. For whatever reason, the manufacturer felt that a 3/16" flat plate would be sufficient. It was bowing just during the mockup. I added a 1"x1/4" strip to the front edge. Should be stiff enough now.

Then I got busy welding the boxing plates to the frame, grinding the welds smooth, hit the surfaces with a flapper disc.

At the very front the upper part of the rail angles in and the bottom stays straight. Since the angles didn't meet, I had to make a filler. Nothing fancy but little jobs like that take time. Several little jobs add up to days of work.

Tried to get a shot of the welds but camera did not want to focus. Basically, it's about 10000 continuous spot welds. Urg.

And there it is. Doesn't look much different does it?

Re: Fuck The Reaper

Posted: Wed Feb 04, 2015 6:45 pm

by 510freak

Sweet c notch, and box.

that sounds,oh heck

looking good Jess

Re: Fuck The Reaper

Posted: Wed Feb 04, 2015 10:19 pm

by wayno

Happy B-Day

Re: Fuck The Reaper

Posted: Thu Feb 05, 2015 6:15 am

by DRIVEN

Thanks guys.

Re: Fuck The Reaper

Posted: Thu Feb 05, 2015 1:11 pm

by izzo

It doesn't look the same to me. Looks much much more finished. Do like! Thanks for the update man

Re: Fuck The Reaper

Posted: Thu Feb 05, 2015 6:04 pm

by DRIVEN

May be the last one for a while. My brother is having some personal complications that he really needs to focus on. I'm letting him off the hook for now. It's officially not going to be ready this summer. I have no need to be in a rush now so It's been moved to the corner while I tackle a couple other projects.

On the upside, I'm seeing a lot more of him now and I'll have an update in the '36 Pickup thread soon.

Re: Fuck The Reaper

Posted: Tue Mar 10, 2015 7:35 pm

by DRIVEN

Reaper update within the week. It's back on.

Re: Fuck The Reaper

Posted: Wed Mar 11, 2015 5:02 am

by 510freak

Sweet

Re: Fuck The Reaper

Posted: Mon Mar 16, 2015 6:16 am

by DRIVEN

I've been back at it. Here's a little confession. I'm a believer that honest build threads should also chronicle the failures and not just the successes. So here's the deal; I

thought I was done with the frame but while I was doing the final cleanup with a flapper disc I noticed something odd. The dust was acting like magnaflux and showing some invisible (with the naked eye) cracks where I had insufficient penetration and essentially had ground away all the weld strength. If I wiped away the dust -- you absolutely could not see anything. It wasn't until I took a hammer and smacked the box plates that I could tell that they weren't solid. It wasn't all the welds, but probably 30% needed to be redone.

I flipped it up on the side and started cutting slots where all the weak welds were and then went about an inch beyond in each direction.

I opened the slots up to about 3/32" and then rewelded them. This time I cranked up the heat a bit. After that I ground everything smooth and performed the hammer test again.

Honestly, I don't think anything bad would have happened if I just left it but I wanted it to be solid. Probably the worst thing that might happen is that

maybe those areas might crack the paint and

possibly some rust might have developed. Structurally speaking I don't think it would have been an issue.

Once I had everything to my liking, I rolled the sand blaster out of the corner and laid out some wet sand to dry for the next couple days. Going by the weather forecast, it looks like Wednesday after work I'll give it a quick cleanup pass then slide it into the booth for a sealer coat. Then the prep work begins.

Jerod will be in town for the swap meet and is really anxious to do some work on it. My goal is to have the frame done and the components ready to hang on it by then. Hopefully there won't be any more distractions.

Re: Fuck The Reaper

Posted: Thu Mar 19, 2015 5:21 am

by DRIVEN

Re: Fuck The Reaper

Posted: Thu Mar 19, 2015 9:38 am

by K_trip

It's coming along nicely

Re: Fuck The Reaper

Posted: Thu Mar 19, 2015 11:26 am

by DRIVEN

Thanks. That's just a primer/sealer coat. Now the real work begins. Pics when there's progress.