So is DATSOON hehe. That might be good.

Wynona the wagon's resurrection!

- wayno

- Posts: 5321

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Wynona the wagon's resurrection!

Special

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5321

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Wynona the wagon's resurrection!

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- HRH

- Posts: 2366

- Joined: Sat Jan 18, 2014 8:54 pm

- Cars: Lots

- Location: Near flatcat

- Has thanked: 147 times

- Been thanked: 649 times

- Taterhead

- Posts: 2494

- Joined: Thu Jul 11, 2013 4:18 am

- Cars: '71 510 - Mine

'72 510 - Sons - Location: Central Alabama

- Has thanked: 1354 times

- Been thanked: 236 times

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Wynona the wagon's resurrection!

5DSC

When the only tool you have is a hammer every problem starts to look like a hippy.

- HRH

- Posts: 2366

- Joined: Sat Jan 18, 2014 8:54 pm

- Cars: Lots

- Location: Near flatcat

- Has thanked: 147 times

- Been thanked: 649 times

Re: Wynona the wagon's resurrection!

^ I like that one!  Keith? Turd ripper? Maybe TRDFERG? (Turd Ferguson) ?

Keith? Turd ripper? Maybe TRDFERG? (Turd Ferguson) ?  But they'd have to have seen old SNL to get that.

But they'd have to have seen old SNL to get that.

"Self proclaimed most active poster on NWD." - Me

- HRH

- Posts: 2366

- Joined: Sat Jan 18, 2014 8:54 pm

- Cars: Lots

- Location: Near flatcat

- Has thanked: 147 times

- Been thanked: 649 times

Re: Wynona the wagon's resurrection!

Oh snap! I know! How about "FLATCAT"?! And then, much madness would ensue! Lol. DAMMIT!! I just checked, someone has flatcat. Awwww.

"Self proclaimed most active poster on NWD." - Me

- Taterhead

- Posts: 2494

- Joined: Thu Jul 11, 2013 4:18 am

- Cars: '71 510 - Mine

'72 510 - Sons - Location: Central Alabama

- Has thanked: 1354 times

- Been thanked: 236 times

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Wynona the wagon's resurrection!

Turd raper?

When the only tool you have is a hammer every problem starts to look like a hippy.

- flatcat19

- Posts: 5233

- Joined: Thu Jun 27, 2013 11:53 am

- Title: AKA Smoke

- Cars: Smaller. Better. Slower. Lower.

- Location: Where you aren't.

- Has thanked: 12 times

- Been thanked: 32 times

Re: Wynona the wagon's resurrection!

TRD Ripper...you know, fuck Toyota and all.

Unless you really wanted a Cressida when you went shopping for a new car...and all you found was a Maxima.

Unless you really wanted a Cressida when you went shopping for a new car...and all you found was a Maxima.

- Taterhead

- Posts: 2494

- Joined: Thu Jul 11, 2013 4:18 am

- Cars: '71 510 - Mine

'72 510 - Sons - Location: Central Alabama

- Has thanked: 1354 times

- Been thanked: 236 times

Re: Wynona the wagon's resurrection!

No, I thought Toyota Racing Development Raper.

But if turd raper is ones thing…

But if turd raper is ones thing…

- Converted_to_datsun

- Posts: 458

- Joined: Fri Jun 28, 2013 3:33 pm

- Cars: 74 Datsun b210, 94 Nissan hard body sas, 07 Ford Focus

- Been thanked: 1 time

- HRH

- Posts: 2366

- Joined: Sat Jan 18, 2014 8:54 pm

- Cars: Lots

- Location: Near flatcat

- Has thanked: 147 times

- Been thanked: 649 times

Re: Wynona the wagon's resurrection!

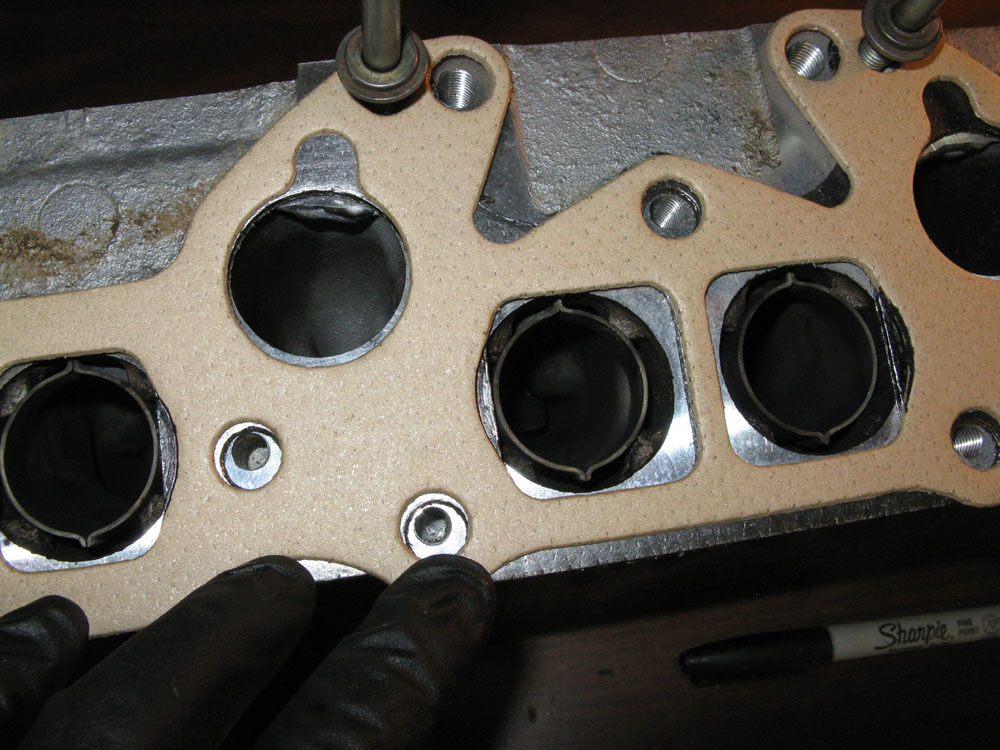

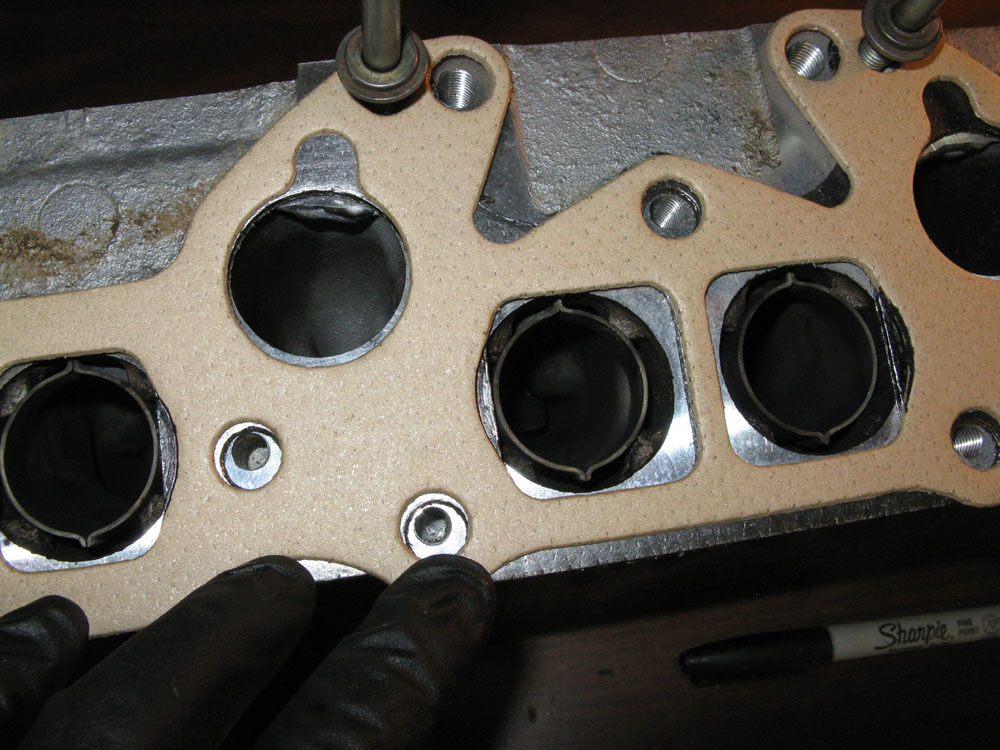

You must be doing something wrong, I get head all the time!  And now, for some pictures! I didn't get nearly as much done as I wanted, due to having to strip down the old head for the valve springs and retainers. The valve spring clamp I have is rather tricky to use without marfing up the edges of the cylinder head. Doable, just have to do a few not in order. Anyway, got the new (original) head ported. Took two tries on that. Started, then checked the gasket again and didn't cut wide enough, so held the gasket on with some spacers and bolts and recircled it again. This time it's perfect. I'm almost thinking of installing a dowel in the intake manifold so I don't have to worry about lining it up so it's perfectly round. We'll see.

And now, for some pictures! I didn't get nearly as much done as I wanted, due to having to strip down the old head for the valve springs and retainers. The valve spring clamp I have is rather tricky to use without marfing up the edges of the cylinder head. Doable, just have to do a few not in order. Anyway, got the new (original) head ported. Took two tries on that. Started, then checked the gasket again and didn't cut wide enough, so held the gasket on with some spacers and bolts and recircled it again. This time it's perfect. I'm almost thinking of installing a dowel in the intake manifold so I don't have to worry about lining it up so it's perfectly round. We'll see.

This is how much needs to be trimmed off the stock L square exhaust gasket if using the round port header.

A sewing store has great scissors for cutting gaskets. A variety helps. Remember, if cutting metal gaskets, these wear out fairly quickly. The curved jaw little scissors are ideal. I finally broke them this time around. It would be nicer to have a straight paper gasket for easier cutting, but alas I only had the fel-pro in my parts room.

Aluminum shavings get EVERYWHERE. Including shirts. Wash these clothes in a separate load.

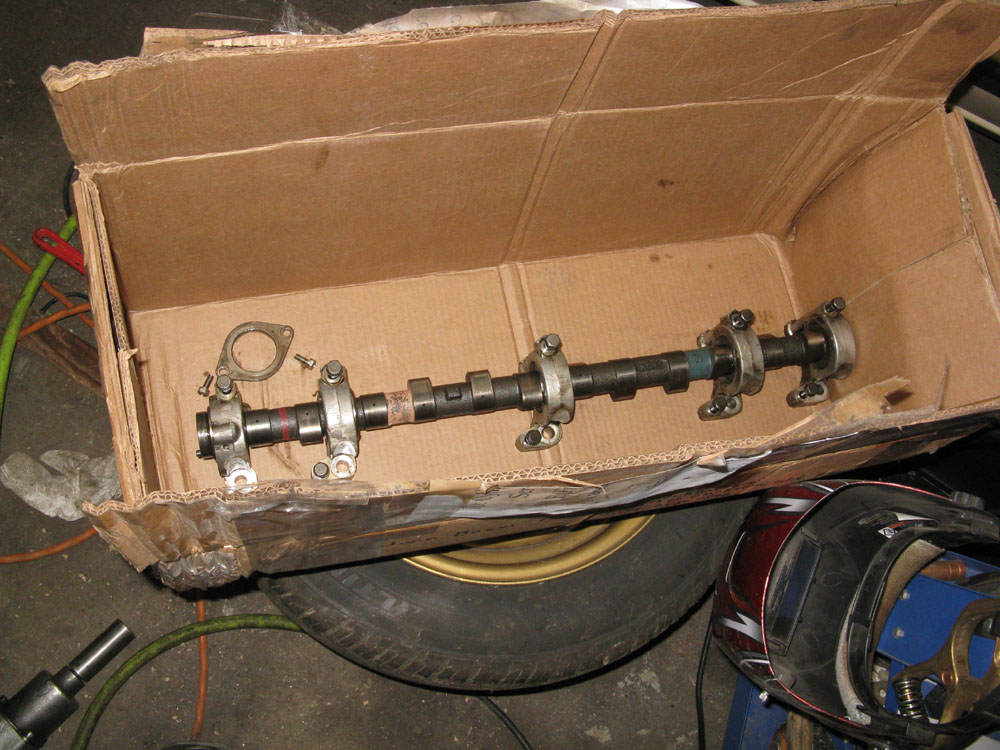

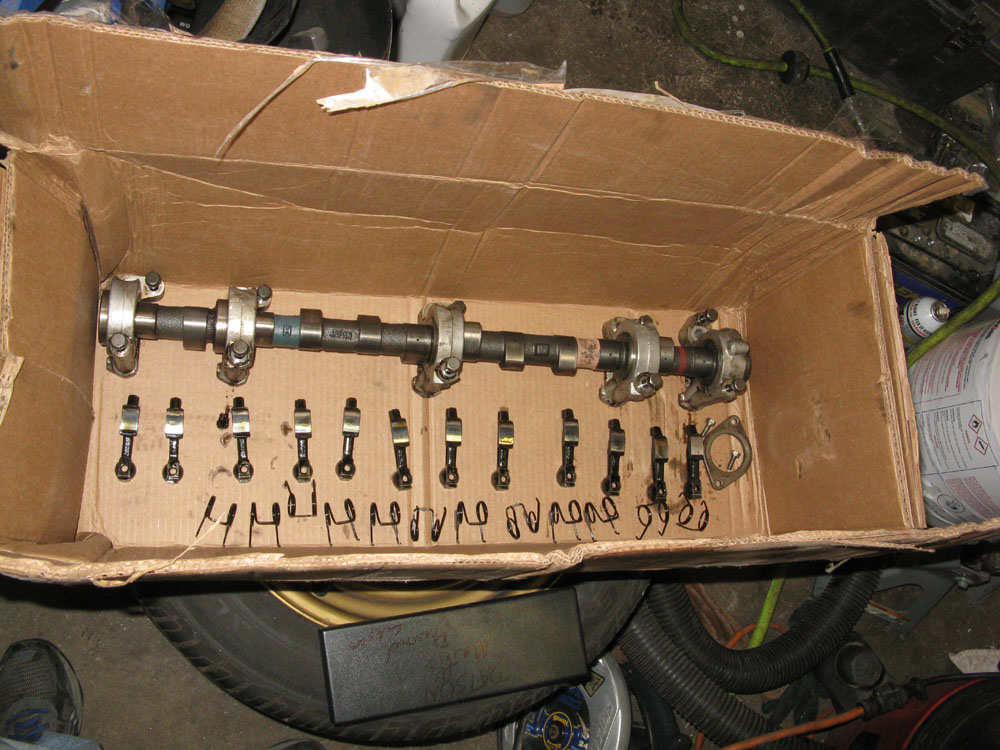

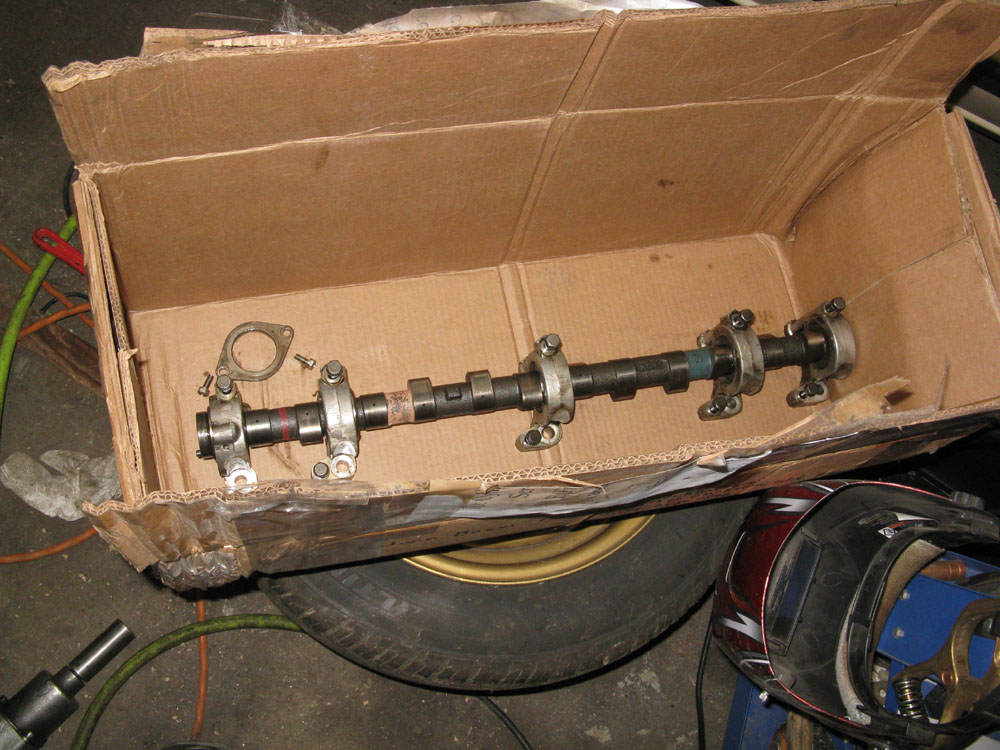

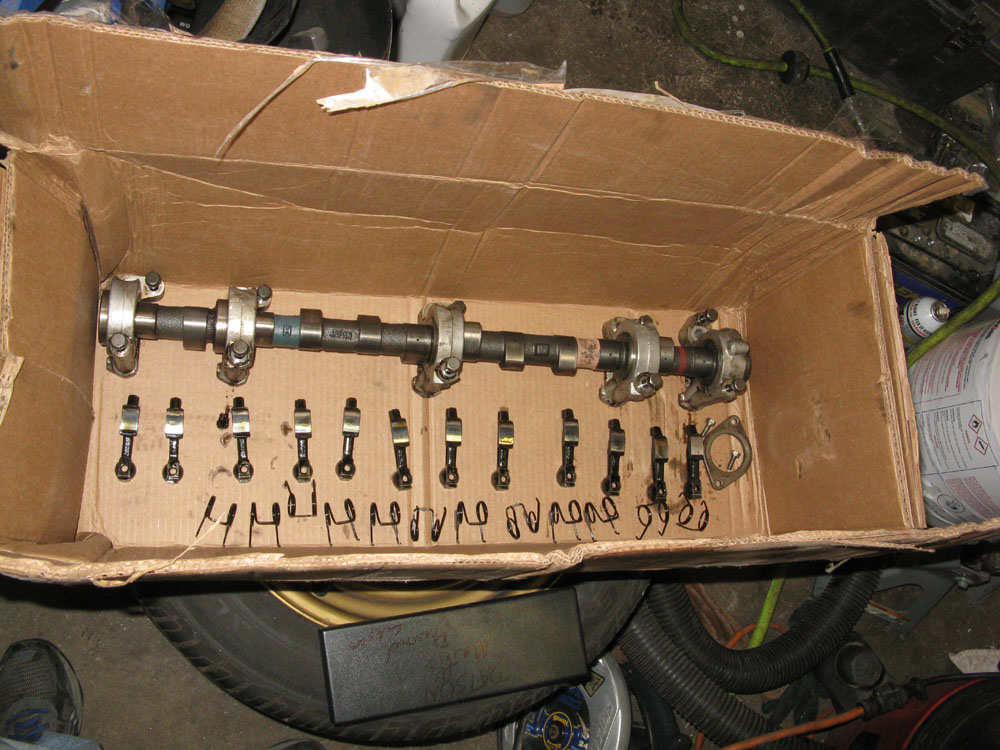

All the little head bits disassembled from the old Ugly Betty head.

I did dink this intake port edge just slightly. I'm sure it will still seal. Annoyed me, the football bit slipped out just a hair.

Almost ready to put the valve springs back in! Pay close attention when doing so. Don't want to scratch the newly cut head surface! The stock head was warped pretty badly from the original detonation-melting of #6. Ended up clearing approximately .018 off it to get it straight again. Not using shims, will just adjust chain slack and fiddle with offset dowel to get appropriate cam position.

So there you go! Progress!

This is how much needs to be trimmed off the stock L square exhaust gasket if using the round port header.

A sewing store has great scissors for cutting gaskets. A variety helps. Remember, if cutting metal gaskets, these wear out fairly quickly. The curved jaw little scissors are ideal. I finally broke them this time around. It would be nicer to have a straight paper gasket for easier cutting, but alas I only had the fel-pro in my parts room.

Aluminum shavings get EVERYWHERE. Including shirts. Wash these clothes in a separate load.

All the little head bits disassembled from the old Ugly Betty head.

I did dink this intake port edge just slightly. I'm sure it will still seal. Annoyed me, the football bit slipped out just a hair.

Almost ready to put the valve springs back in! Pay close attention when doing so. Don't want to scratch the newly cut head surface! The stock head was warped pretty badly from the original detonation-melting of #6. Ended up clearing approximately .018 off it to get it straight again. Not using shims, will just adjust chain slack and fiddle with offset dowel to get appropriate cam position.

So there you go! Progress!

"Self proclaimed most active poster on NWD." - Me