Page 23 of 39

Re: The "Retired" 510

Posted: Mon May 22, 2017 8:02 pm

by noflers

I'd love to take the 510, but I'm afraid it's just not big enough. I'll most likely take the Outback on the trip, still waiting on final confirmation for the trip... No A/C either way

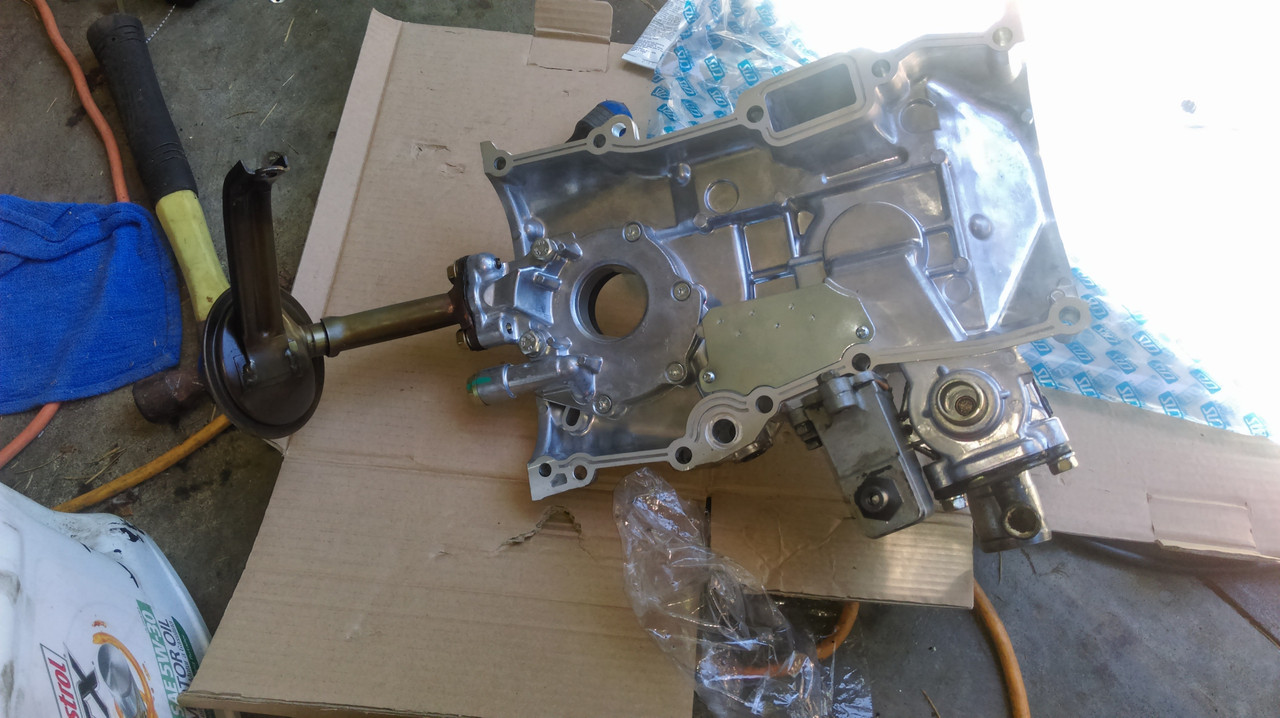

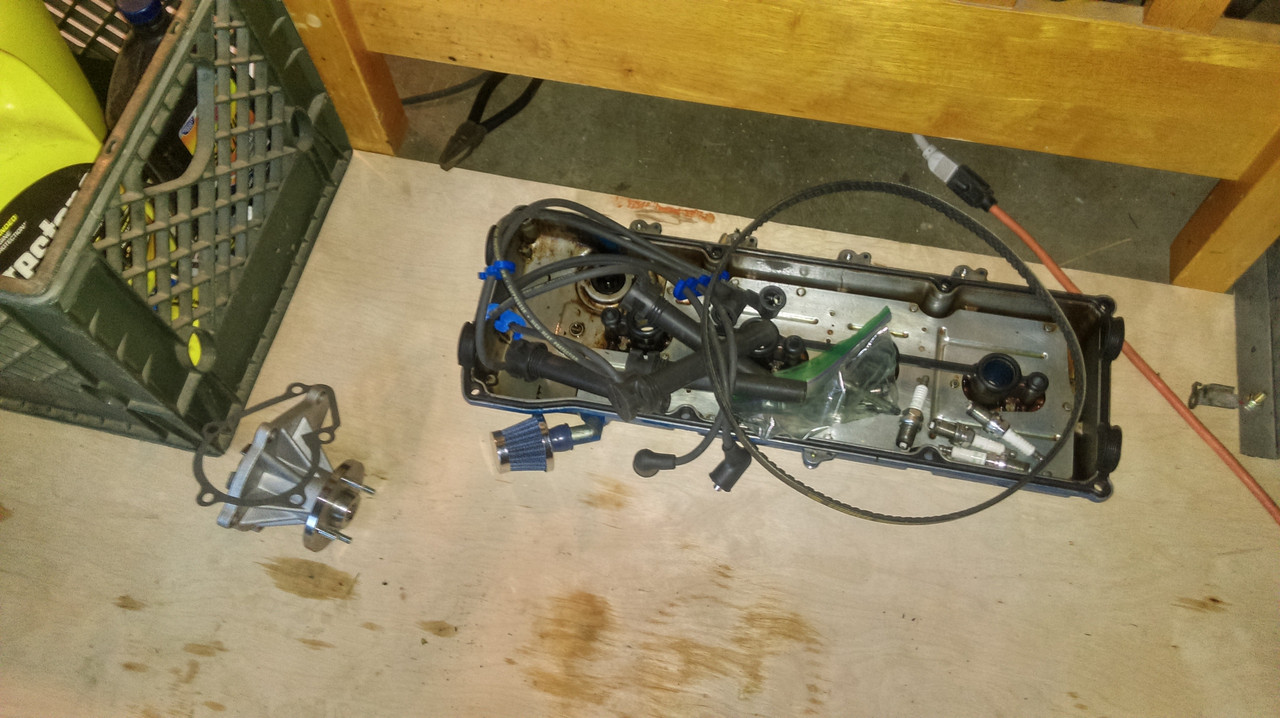

I did a simple valve leak test and found a couple bad seals on the exhaust side, and one on the intake side. I ordered two intake valves just in case the two that made contact with piston 4 are bent. They have a good seal, but could they still be bent at that point? Or could they be okay? [url=

https://postimg.cc/image/wfzh3p69t/]

Ya know, I think the only time I cursed while taking the motor apart was when I saw the head gasket, and I've learned that really wasn't so bad. But yeah, Nissan can fuck off right about now.

Re: The "Retired" 510

Posted: Wed May 24, 2017 5:54 am

by 510freak

Yikes no A/C on a trip to cali.

Did that many times in the 510.friggin hot!

Re: The "Retired" 510

Posted: Wed May 24, 2017 10:28 am

by noflers

I actually have a guy coming over to service my A/C in the Subaru this week. Compressor and everything work, but there's a leak in the system somewhere. Charged it up last summer and it all leaked out within three days... I'll be in Humboldt, so it'll be hot, but not like SoCal hot. Timing belt and associated crap needs to be done before I leave too, idler gears and whatnot are getting pretty noisy. It's hard to put any money in the motor when I know the rings are bad and probably valve stem seals. It's never ending!!!!!!

I guess I was mixed up before. After I removed the intake manifold I noticed that it had an SCV and throttle plates. I thought that they didn't start using that until the S14, but I was backwards, they stopped using it on the S14. I removed the valve and plates, but left the rod in place. I'm pretty confident that's what was why it seemed like power choked out at half throttle or more. We shall see...

You can sort of see the plates just inside of each runner here

They're gone now

And good news from the machine shop, no bent valves!

Re: The "Retired" 510

Posted: Wed May 24, 2017 1:33 pm

by izzo

My wife keeps getting at me for AC lol.. But we don't get many hot days around here. Maybe a week or two out of the year thats pretty hot

Re: The "Retired" 510

Posted: Wed May 24, 2017 2:15 pm

by noflers

Lol, I've never had AC until I got the Subaru, now it sucks without it.

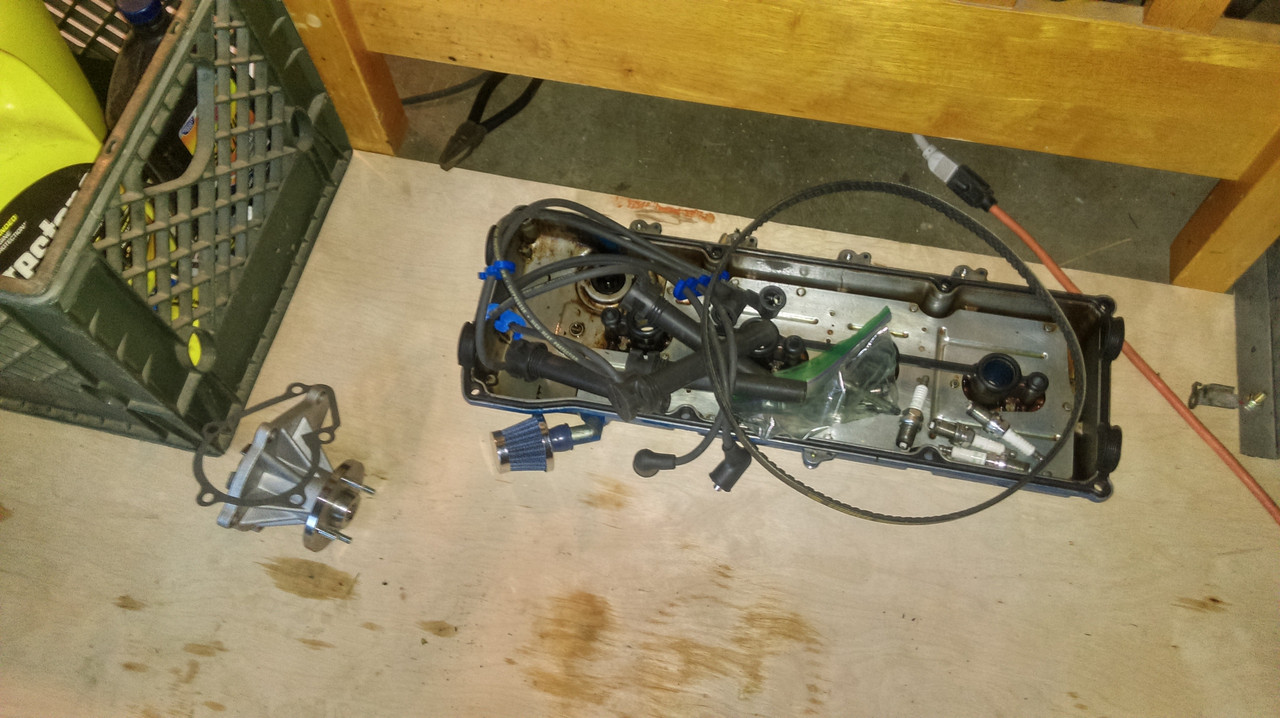

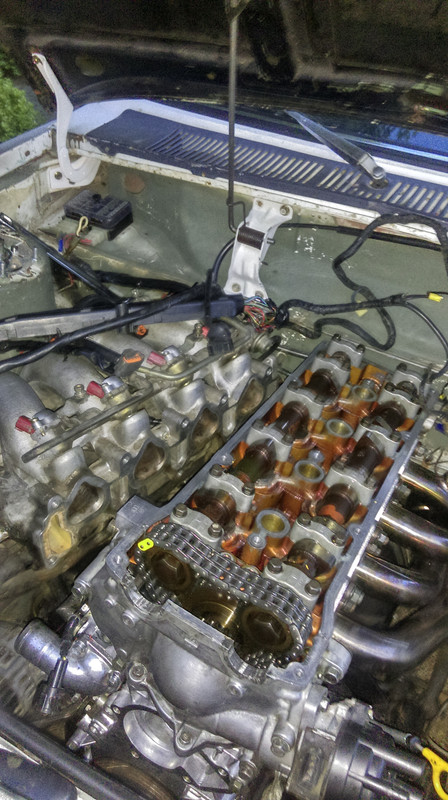

Heads back from the shop. Time to get back to work!

Re: The "Retired" 510

Posted: Wed May 24, 2017 4:41 pm

by DRIVEN

#1 most common AC leak on Subarus is the Oring on the hose that connects to the back of the compressor. And please don't use any of those zip cans that have stop leak in them. It fucks up any AC machine that gets hooked up to your car in the future ($1-2K equipment repair) and eventually ruins your system too.

Re: The "Retired" 510

Posted: Thu May 25, 2017 5:04 pm

by noflers

Re: The "Retired" 510

Posted: Thu May 25, 2017 8:00 pm

by noflers

I lied, ended up putting the oil pan on and got the motor set back down. Tomorrow can be an easy day now. Just need to get these few little things back together and I can start it up.

Re: The "Retired" 510

Posted: Fri May 26, 2017 5:07 am

by DRIVEN

Man, you really, really don't screw around.

Re: The "Retired" 510

Posted: Fri May 26, 2017 10:35 am

by noflers

Until I do something like this. Totally forgot to put a house clamp here. Good thing it started leaking as soon as the coolant got to it or I might not have noticed until it was too late.

Now, how the hell can I do this without pulling the intake manifold again? I'm about to the point where 10 zip ties will have to do.

Re: The "Retired" 510

Posted: Fri May 26, 2017 1:42 pm

by noflers

This was the easiest way I could see, and it still wasn't easy! Replaced the throttle body gasket while it was off too.

I must have earned some compression back, the motor is noticeably harder to turn over by hand and even the starter wasn't having it for more than a couple turns.

Doing the whole crank engine forever and hope the oil system is primed thing right now. Should have a new video soon.

Re: The "Retired" 510

Posted: Fri May 26, 2017 2:31 pm

by noflers

Well fuck me. I fucked it up. Compression going straight into the coolant. The whole neighborhood is smoked out. And the starter isn't engaging properly anymore. FML. I'm so upset with myself, I don't know what to think.

Does the head need to come off or can I just pull cams and retorque the head?

Re: The "Retired" 510

Posted: Fri May 26, 2017 2:42 pm

by noflers

Pulled the plugs and smoke was only coming out of cylinder 1.

Re: The "Retired" 510

Posted: Sat May 27, 2017 8:34 am

by noflers

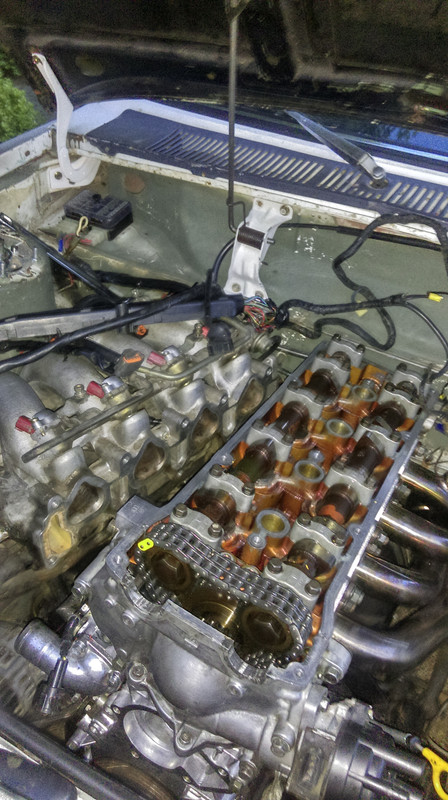

So I'm a little more relaxed about the situation. I got the motor torn back down by just involving the exhaust and upper timing cover and lifting with the crane. I was able to get 3-4" of clearance that way, should have no problem getting in there to clean and place a new gasket. It was so sad to see a practically new gasket and set of bolts go in the trash

I'll return later with a better outcome.

Re: The "Retired" 510

Posted: Sat May 27, 2017 10:18 am

by DRIVEN

Did you see where it was leaking and why?

Re: The "Retired" 510

Posted: Sat May 27, 2017 11:07 am

by noflers

Coolant was getting into cylinder 1 at a high rate. Smoke was coming from there when I pulled the plugs. The very front right head bolt was a bit loose. The gasket looked okay, but I didn't run the engine very long.

Re: The "Retired" 510

Posted: Sun May 28, 2017 7:04 am

by 510freak

Well boo,At the rate you are motivated,it will be back together again,by days end

Re: The "Retired" 510

Posted: Sun May 28, 2017 8:39 am

by noflers

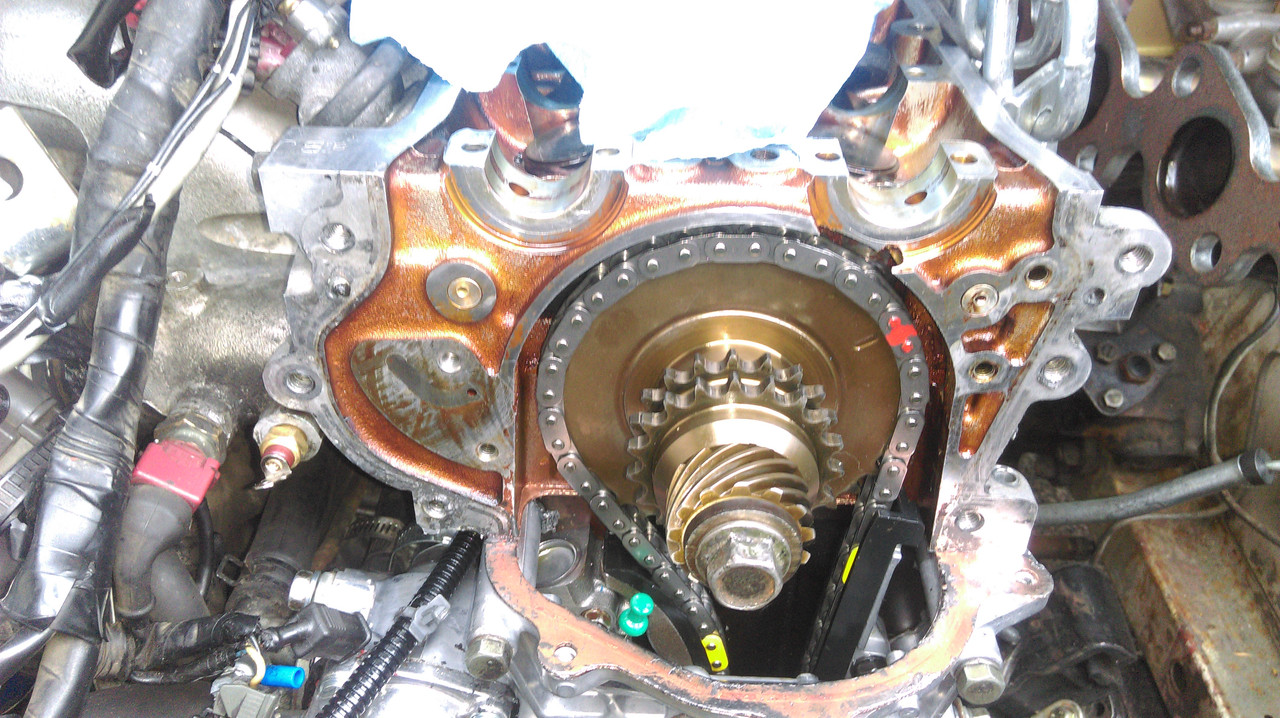

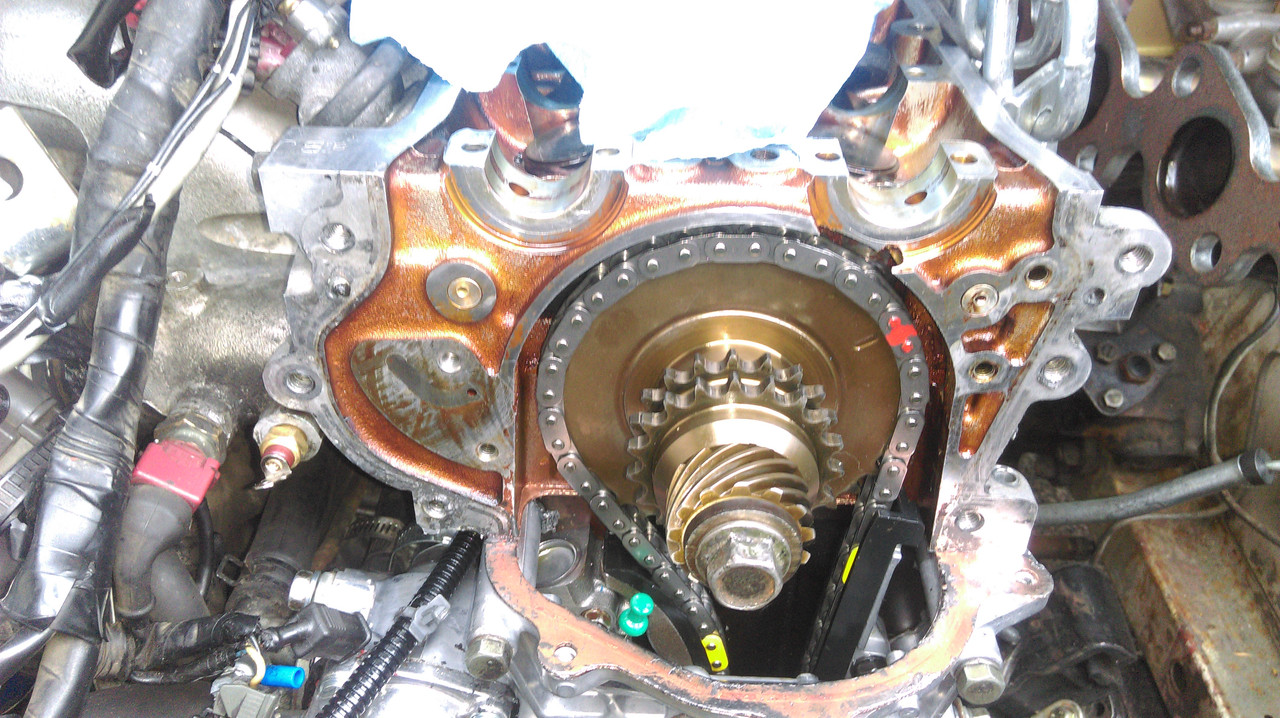

I think it's gonna be a few more days... The idler gear bolt hole stripped out, with only factory torque specs. I did some searching and it's not super common, but it's happened to at least a few people. I found this how-to where the guy pressed a threaded insert into the upper cover so a set screw could be used to stabilize the side loading on the idler gear bolt.

http://community.ratsun.net/topic/66809 ... ocket-fix/ I think the only thing I'd do differently is to actually drill a very shallow hole in the bolt itself and tap a few threads into it. Then use a stud with a nut+lock nut to keep it in there. That's a bit more work than I'm wanting to get into, but could happen in the future.

If any of you have taken this motor apart, you'll know that there's a few problem bolts, including this one. I've already repaired the threads on 5 other holes, all M6x1.0, in the valve cover and oil pan, this will be the biggest at M12x1.25. It's been mentioned before by others, but I took my own measurements anyway. The idler gear bolt is barely over 10mm too short compared to the hole it goes in. I'll also be ordering a new bolt for this application from McMaster-Carr. Unfortunately they can only be had in boxes of 5. If anyone needs one let me know, otherwise they'll be lost in the garage in no time. With an additional 10mm of thread grabbing, the longer bolt alone would better if your threads are still good. Jacob, does the CA18 use this same bolt? Probably not, but figured it's worth it to ask. Also, while trying to figure this out I found multiple people who say not to torque some of the bolts on the head to factory spec because the threads are so prone to strip.

To make matters worse, after I wiggled the idler gear out, the chain dropped inside, FML. It wasn't so bad getting it back out though. I just used a bucket handle bent to my specs and it took about 20 seconds. I'm not sure if the chain moved on the lower sprocket (is that possible?), but I have a feeling it didn't since the link I marked on the upper sprocket seems to be in the same spot. No matter what happens after this point, I am absolutely NOT pulling the front cover and oil pan again.

My head is already torqued back on, so I'll be trying to fix this with the head still on. Might go like this: unbolt engine mounts, lift engine as far as I can (giving me straight shot access to the bolt hole), drill tap and insert Helicoil. Wish me luck!

Re: The "Retired" 510

Posted: Sun May 28, 2017 5:50 pm

by DRIVEN

Sucky

Re: The "Retired" 510

Posted: Tue May 30, 2017 5:11 pm

by noflers

All is well now. I found this old subaru alignment bolt in one of my bolt buckets 12x1.25x110 I ground the end of the bolt down as it was tapered and I wanted to be sure it wouldn't be seating in the bottom of the bolt hole. It's now about 107mm long.

Here's the Heli coil process.

Drilled out to 31/64"

Tapped with the unknown size helicoil tap

Coil inserted

Idler gear reinstalled, torqued to 75 ft-lbs

Going to triple check head bolt torque and proceed