This is a "How to - Lap your valves" general guide tutorial.

You can do this process yourself or take it down to an automotive machine shop to have them do it for you.

Materials needed.

* a LOOSE Cylinder head to be worked on.

* Valve Spring Compressor.

* Valve grinding compound.

* Valve grinding tools.

* Extendable small magnet.

* Wet damp lint free cloth... a few of these at least is a good idea.

* Repair manual (trusted).

* A few containers or a large container that is numbered to keep all valve components in order/numbered #.

* and... common sense.

NOTE: In earlier heads with softer seats you're going to want to check your valve to rocker clearances (example meaning: --the maximum clearance when the lifter head is spun down all the way into the head) to see if the valve face/and/or seat are severely worn. If they are it's entirely possibly to grind valves on a current head into softer seats/worn parts to allow NO adjustment or slack (which is needed) when you're done. This especially apply's to "new to you" heads that have never been run. Later cylinder heads such as this 1981 280zx P79 OHC aluminum cylinder head had harder seats , and better valves.

We are working on an already loose from the engine cylinder head.

(STEP 1) --- Break loose the 19mm bolt at the front of the camshaft , but do not remove quite yet (if you have an impact wrench or gun you can do this step later). Remove the rocker retainer springs on all rockers , and set aside in order. Go ahead , and break loose the adjustment on the lifters with a 14mm , and 17mm wrench. Next spin the clock-wise so that the lifters head goes downward into the cylinder head. Spin the cam carefully while noting which lobes are point ^ upwards. These are the ones you want to remove the rockers from first. Place them carefully in order on the exact position in which they came off the head along with a note/holder. Do the same for all cylinder head parts related.

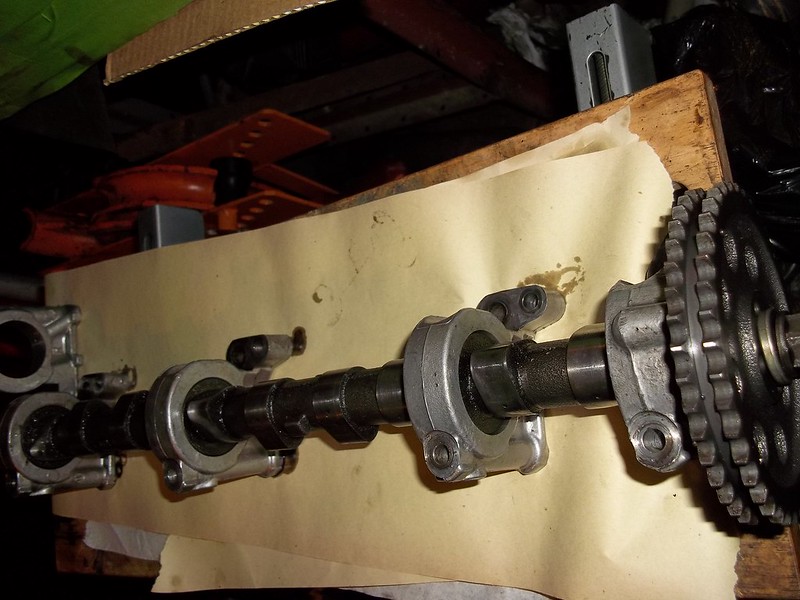

(STEP 2) --- Pull out or remove the camshaft. You cam either un-bolt the retainer at the front with a 19mm impact wrench + 10mm wrench. Some people chose to remove the cam towers , and lift the cam-shaft/towers off directly (as the camshaft towers are aligned with hollow dowels for re-placement). I choose to pull the camshaft out the front this particular time. Another time I pulled the camshaft towers with the camshaft. Carefully and slowly supporting it evenly throughout the process with plenty of lube if pulling only the camshaft.

017 by 71240z, on Flickr

017 by 71240z, on Flickr 002 by 71240z, on Flickr

002 by 71240z, on FlickrCamshaft is out.

010 by 71240z, on Flickr

010 by 71240z, on Flickr(STEP 3) --- Optional. I taped up the cam towers to keep grit/crap/debris from getting in while the head was apart. There are (2) main oil gallery holes feeding all the towers on the bottom that received some green tape. Also non-related is I removed the lifters from this head to switch them with another set. Not required for lapping valves.

008 by 71240z, on Flickr

008 by 71240z, on Flickr(STEP 4) --- Grab your valve spring compressor. Mine looks like a big "C" design. Yours maybe an overhead or leverage of some type design. Grab your extendable magnet as well (for extracting the valve keepers once the valve springs are compressed.)

001 by 71240z, on Flickr

001 by 71240z, on Flickr