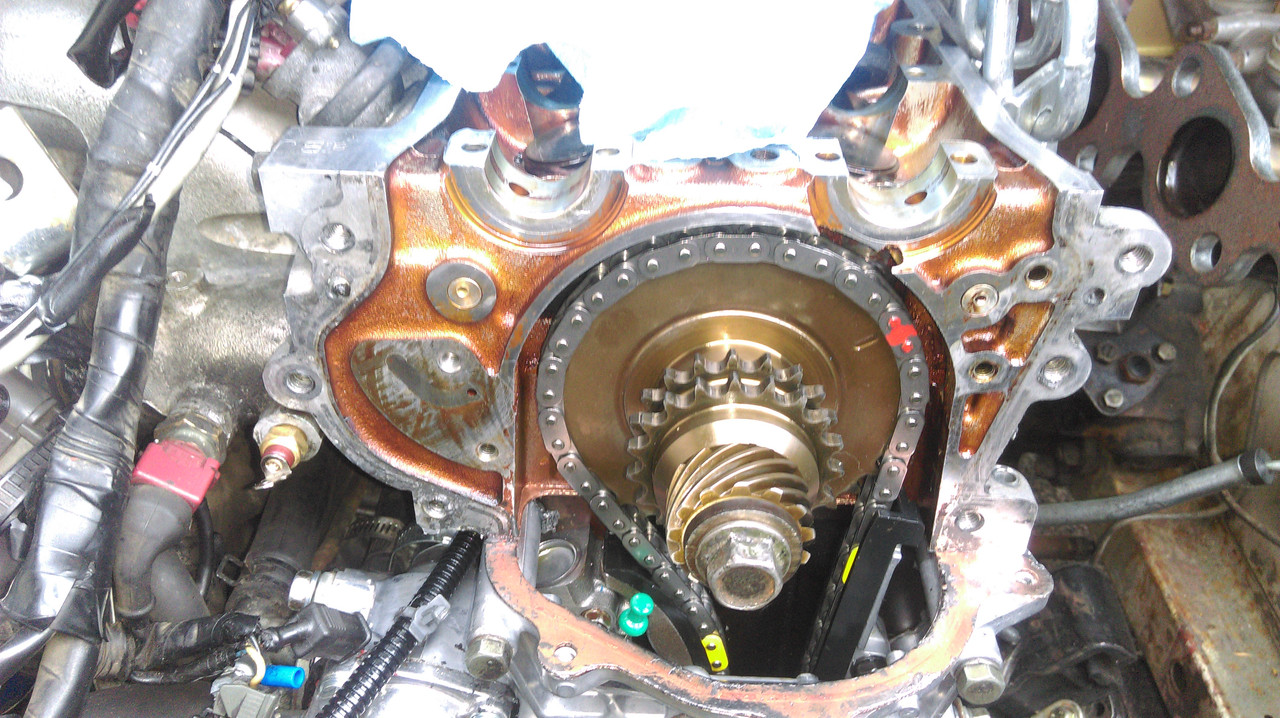

I think it's gonna be a few more days... The idler gear bolt hole stripped out, with only factory torque specs. I did some searching and it's not super common, but it's happened to at least a few people. I found this how-to where the guy pressed a threaded insert into the upper cover so a set screw could be used to stabilize the side loading on the idler gear bolt.

http://community.ratsun.net/topic/66809 ... ocket-fix/ I think the only thing I'd do differently is to actually drill a very shallow hole in the bolt itself and tap a few threads into it. Then use a stud with a nut+lock nut to keep it in there. That's a bit more work than I'm wanting to get into, but could happen in the future.

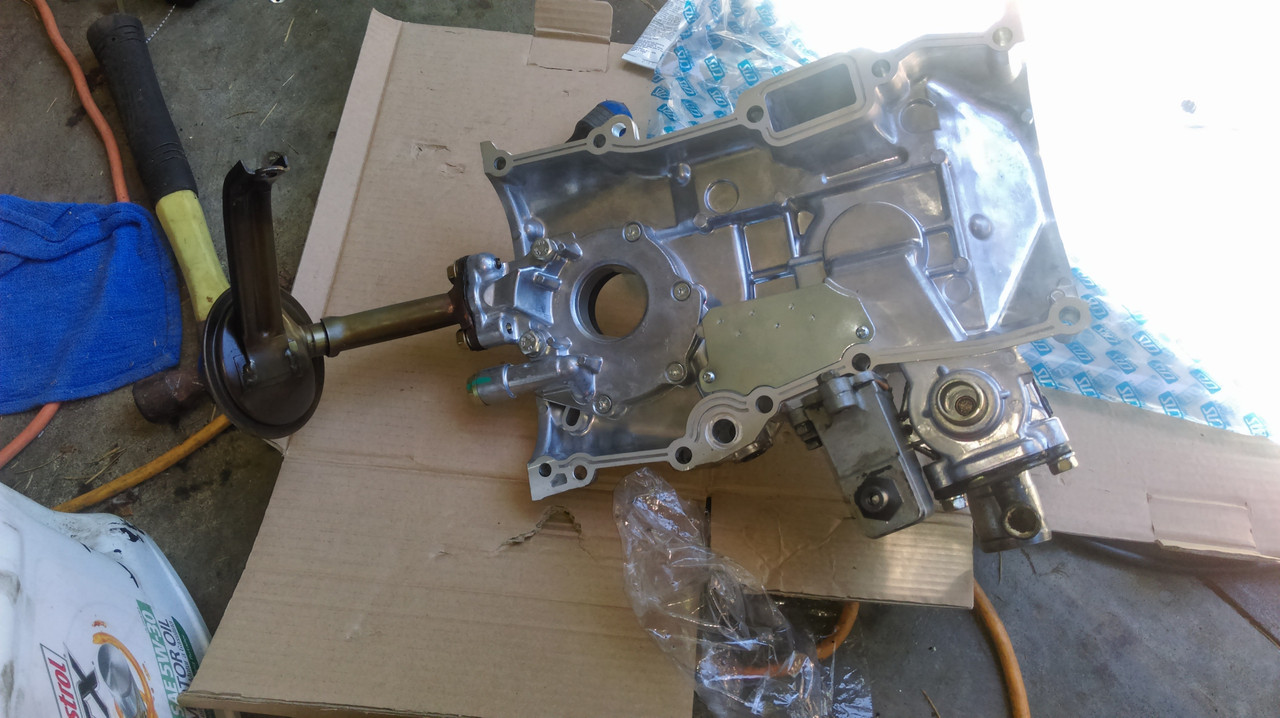

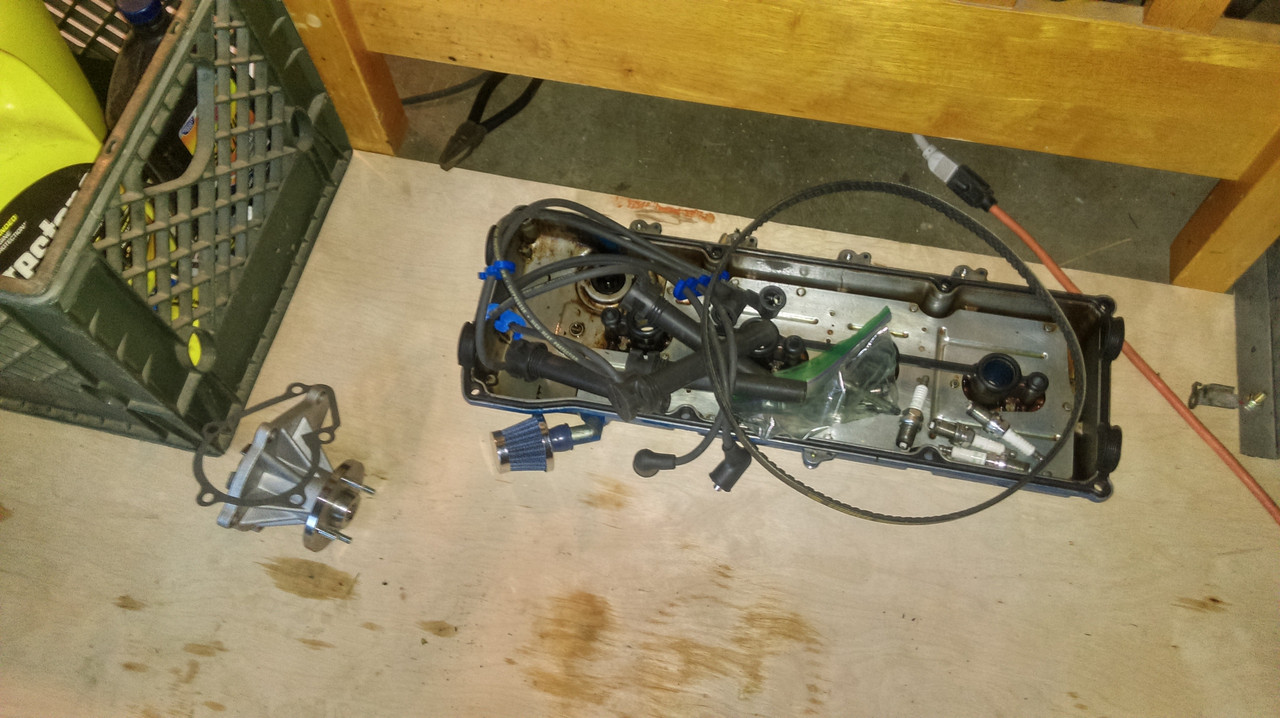

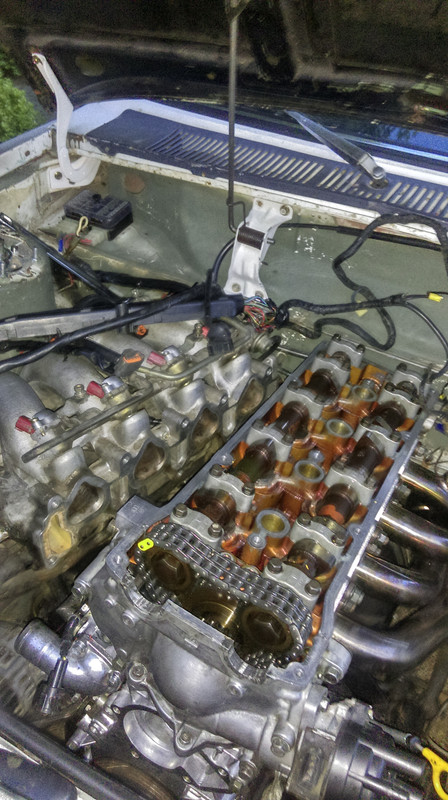

If any of you have taken this motor apart, you'll know that there's a few problem bolts, including this one. I've already repaired the threads on 5 other holes, all M6x1.0, in the valve cover and oil pan, this will be the biggest at M12x1.25. It's been mentioned before by others, but I took my own measurements anyway. The idler gear bolt is barely over 10mm too short compared to the hole it goes in. I'll also be ordering a new bolt for this application from McMaster-Carr. Unfortunately they can only be had in boxes of 5. If anyone needs one let me know, otherwise they'll be lost in the garage in no time. With an additional 10mm of thread grabbing, the longer bolt alone would better if your threads are still good. Jacob, does the CA18 use this same bolt? Probably not, but figured it's worth it to ask. Also, while trying to figure this out I found multiple people who say not to torque some of the bolts on the head to factory spec because the threads are so prone to strip.

To make matters worse, after I wiggled the idler gear out, the chain dropped inside, FML. It wasn't so bad getting it back out though. I just used a bucket handle bent to my specs and it took about 20 seconds. I'm not sure if the chain moved on the lower sprocket (is that possible?), but I have a feeling it didn't since the link I marked on the upper sprocket seems to be in the same spot. No matter what happens after this point, I am absolutely NOT pulling the front cover and oil pan again.

My head is already torqued back on, so I'll be trying to fix this with the head still on. Might go like this: unbolt engine mounts, lift engine as far as I can (giving me straight shot access to the bolt hole), drill tap and insert Helicoil. Wish me luck!