Waynos work truck.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

So I went and bought oil and filter this morning.

When I got home I looked under the truck and seen oil around where I welded up the hole, I wasn't all that happy, still after welding on it some more I am not sure it is fixed but I installed the filter and added the oil anyway and will watch it, my weld job on the other pan worked great.

I tested the pedals and they appear to be the same as yesterday so that is good.

Next I drilled a large hole for the rear wiring harness to come into the cab that has a rubber grommet, I found a hole saw the right size, but I was just going to make an existing hole larger, that doesn't work very well for the pilot drill bit to keep the hole saw from wandering, so I found a piece of scrap sheet metal and drilled a hole in it on my drill press, I then centered the scrap metal hole over the smaller hole and then stood on the scrap metal to hold it still, then I used it to keep the hole saw from wandering, it worked alright, the grommet fits the hole so I suppose it worked great, I then had them wires inside the cab, I used a jumper wire and used the cigarette lighter power to test the fuel pump, it worked great.

Next I took the worthless fuel pump off the engine and put a plate/cover over the hole, I then piped the fuel lines from the outlet next to the starter to the new fuel filter in the stock position, then I made the fuel line going to the hard line going to the SUs, but I tested the fuel pump first, I put 5 gallons in the tank and gave it power and pumped fuel out the other end then I connect that fuel line to the hard line.

I looked at the oil pan again and it was still dry, but I have no oil in it yet.

I finished wiring the distributor and temp gauge, and then started looking for anything I may have forgot, looked at the oil pan again.

So I started with fluids, I filled the PS pump/reservoir, topped off the SUs, added the oil, I then installed the battery, the radiator is still dry at this point, I put the key in and turned it to the on position and the ignition light came on, the oil light didn't come on, I will deal with that later, it all looked good, no fuses blew so I pulled the choke on and turned it over, it started weird and ran badly but it was running, it kept trying to die unless I pulled the choke full on, after a minute at at least 2000rpms I shut it down and went looking for a vacuum leak, well it turned out to be the SU linkage, one SU was being held open at maybe 1/3 throttle, I had to remove the front SU and set up the linkage properly, I then filled the radiator with water and started it again, it was loud but it ran properly, I checked the oil pan and there was a drip of oil on it.

I then focused on the exhaust, the end of the header has a flange, but after looking at it if I were to cut the flange off the pipe goes oval almost right away, so I made a flange which was not easy for me as I don't have 2 1/2 inch hole saws, so I used my 1 1/2 inch hole saw and made a hole, I then proceeded to use a tall cylinder type grinding stone I have(bought around 6 of them likely 10 years ago) that spins onto my Dewalt grinder and I went around in a circle in that hole for a very long time till I could tap the head pipe into the hole, I then welded them together, then I drilled the flange(I did this in the wrong order) to fit the header flange, I had to notch the transmission cross member, I may pull in out after I am done with the exhaust and beef it up with a quarter circle welded in it like I did when I notched my rear frame on the 520 when I lowered it.

That is where I am now, tomorrow I will go buy a piece of flex exhaust pipe if I can find one the correct size, the muffler is shot so once it is on the road I will likely take it to the muffler shop and have a new system put in.

I lost another Dewalt grinder today, it quit running until I spun it, then while cutting the transmission cross member it started spitting material out of the angle head shaft end, it went to half speed and had no power, and then once I let it come to a stop it would not run anymore, I didn't over heat it, I rebuilt this ones end with an old one I had that the motor had quit maybe 6 months ago, well the motor has quit on this one now, I used the new one I had bought 6 months ago to finish, that is 2 Dewalt grinders in 6 months, but they both were old(one maybe over 10 years old) and I use the shit out of them.

Oh, and the last time I looked at the oil pan after it was warmed up it was dry again.

Tomorrow the exhaust will be finished(temporary) and I will drop the truck on the ground and see if it starts and stops, if it does then I will start on the flatbed, I have everything I need.

When I got home I looked under the truck and seen oil around where I welded up the hole, I wasn't all that happy, still after welding on it some more I am not sure it is fixed but I installed the filter and added the oil anyway and will watch it, my weld job on the other pan worked great.

I tested the pedals and they appear to be the same as yesterday so that is good.

Next I drilled a large hole for the rear wiring harness to come into the cab that has a rubber grommet, I found a hole saw the right size, but I was just going to make an existing hole larger, that doesn't work very well for the pilot drill bit to keep the hole saw from wandering, so I found a piece of scrap sheet metal and drilled a hole in it on my drill press, I then centered the scrap metal hole over the smaller hole and then stood on the scrap metal to hold it still, then I used it to keep the hole saw from wandering, it worked alright, the grommet fits the hole so I suppose it worked great, I then had them wires inside the cab, I used a jumper wire and used the cigarette lighter power to test the fuel pump, it worked great.

Next I took the worthless fuel pump off the engine and put a plate/cover over the hole, I then piped the fuel lines from the outlet next to the starter to the new fuel filter in the stock position, then I made the fuel line going to the hard line going to the SUs, but I tested the fuel pump first, I put 5 gallons in the tank and gave it power and pumped fuel out the other end then I connect that fuel line to the hard line.

I looked at the oil pan again and it was still dry, but I have no oil in it yet.

I finished wiring the distributor and temp gauge, and then started looking for anything I may have forgot, looked at the oil pan again.

So I started with fluids, I filled the PS pump/reservoir, topped off the SUs, added the oil, I then installed the battery, the radiator is still dry at this point, I put the key in and turned it to the on position and the ignition light came on, the oil light didn't come on, I will deal with that later, it all looked good, no fuses blew so I pulled the choke on and turned it over, it started weird and ran badly but it was running, it kept trying to die unless I pulled the choke full on, after a minute at at least 2000rpms I shut it down and went looking for a vacuum leak, well it turned out to be the SU linkage, one SU was being held open at maybe 1/3 throttle, I had to remove the front SU and set up the linkage properly, I then filled the radiator with water and started it again, it was loud but it ran properly, I checked the oil pan and there was a drip of oil on it.

I then focused on the exhaust, the end of the header has a flange, but after looking at it if I were to cut the flange off the pipe goes oval almost right away, so I made a flange which was not easy for me as I don't have 2 1/2 inch hole saws, so I used my 1 1/2 inch hole saw and made a hole, I then proceeded to use a tall cylinder type grinding stone I have(bought around 6 of them likely 10 years ago) that spins onto my Dewalt grinder and I went around in a circle in that hole for a very long time till I could tap the head pipe into the hole, I then welded them together, then I drilled the flange(I did this in the wrong order) to fit the header flange, I had to notch the transmission cross member, I may pull in out after I am done with the exhaust and beef it up with a quarter circle welded in it like I did when I notched my rear frame on the 520 when I lowered it.

That is where I am now, tomorrow I will go buy a piece of flex exhaust pipe if I can find one the correct size, the muffler is shot so once it is on the road I will likely take it to the muffler shop and have a new system put in.

I lost another Dewalt grinder today, it quit running until I spun it, then while cutting the transmission cross member it started spitting material out of the angle head shaft end, it went to half speed and had no power, and then once I let it come to a stop it would not run anymore, I didn't over heat it, I rebuilt this ones end with an old one I had that the motor had quit maybe 6 months ago, well the motor has quit on this one now, I used the new one I had bought 6 months ago to finish, that is 2 Dewalt grinders in 6 months, but they both were old(one maybe over 10 years old) and I use the shit out of them.

Oh, and the last time I looked at the oil pan after it was warmed up it was dry again.

Tomorrow the exhaust will be finished(temporary) and I will drop the truck on the ground and see if it starts and stops, if it does then I will start on the flatbed, I have everything I need.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Waynos work truck.

That's a lot of words.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Yea I talk to much.

First I went to the Costless auto parts and got the flex exhaust line and clamps, I could hardly believe they had the size I needed.

Exhaust is done and it has never been that quiet before that I can recall, I have been so used to exhaust leaks and listening to that thin header that it sounded weird when I started it.

Next I worked on the e-brakes, I had to put a 720 e-brake lever in the truck, I found one that pointed down instead of straight forward, it works great and I need it in case the brakes don't work.

I dropped it on the ground and drove it up and down my street, I slammed the brakes real hard and it locked up, the brakes work fine, the truck rides a bit stiff, but it doesn't have a bed yet, while I was under the truck I connected up the speedo cable.

The last thing I did was mount the front bumper and the grill, it took a little time to make the adapter brackets to fit it to the 720 chassis/frame but all went well.

It is still on the jumper wire for the fuel pump, need to fix that tomorrow, I keep forgetting to unplug it, I just went out and made sure it was unplugged.

I also need to empty the water out of the radiator/engine and put the anti-freeze back in it before it gets cold.

First I went to the Costless auto parts and got the flex exhaust line and clamps, I could hardly believe they had the size I needed.

Exhaust is done and it has never been that quiet before that I can recall, I have been so used to exhaust leaks and listening to that thin header that it sounded weird when I started it.

Next I worked on the e-brakes, I had to put a 720 e-brake lever in the truck, I found one that pointed down instead of straight forward, it works great and I need it in case the brakes don't work.

I dropped it on the ground and drove it up and down my street, I slammed the brakes real hard and it locked up, the brakes work fine, the truck rides a bit stiff, but it doesn't have a bed yet, while I was under the truck I connected up the speedo cable.

The last thing I did was mount the front bumper and the grill, it took a little time to make the adapter brackets to fit it to the 720 chassis/frame but all went well.

It is still on the jumper wire for the fuel pump, need to fix that tomorrow, I keep forgetting to unplug it, I just went out and made sure it was unplugged.

I also need to empty the water out of the radiator/engine and put the anti-freeze back in it before it gets cold.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Waynos work truck.

Home stretch!

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

I likely have another week at least, but I am only working on it 5/6 hours a day and I don't get a lot done in that time either.

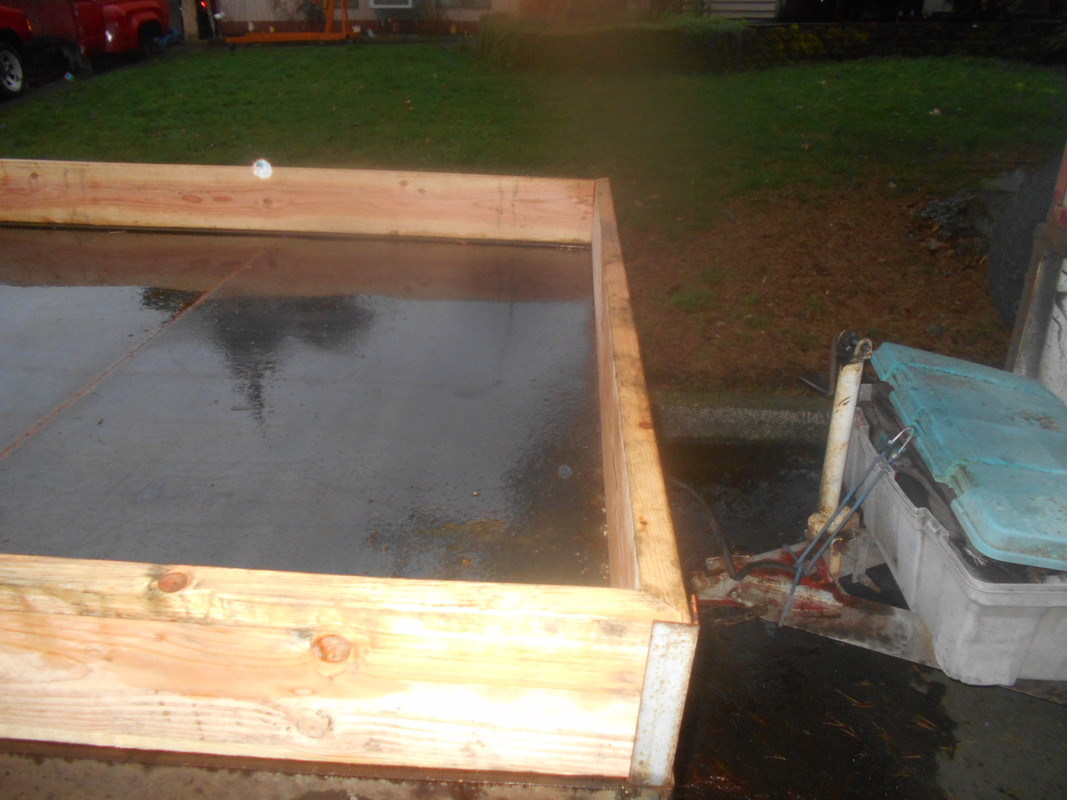

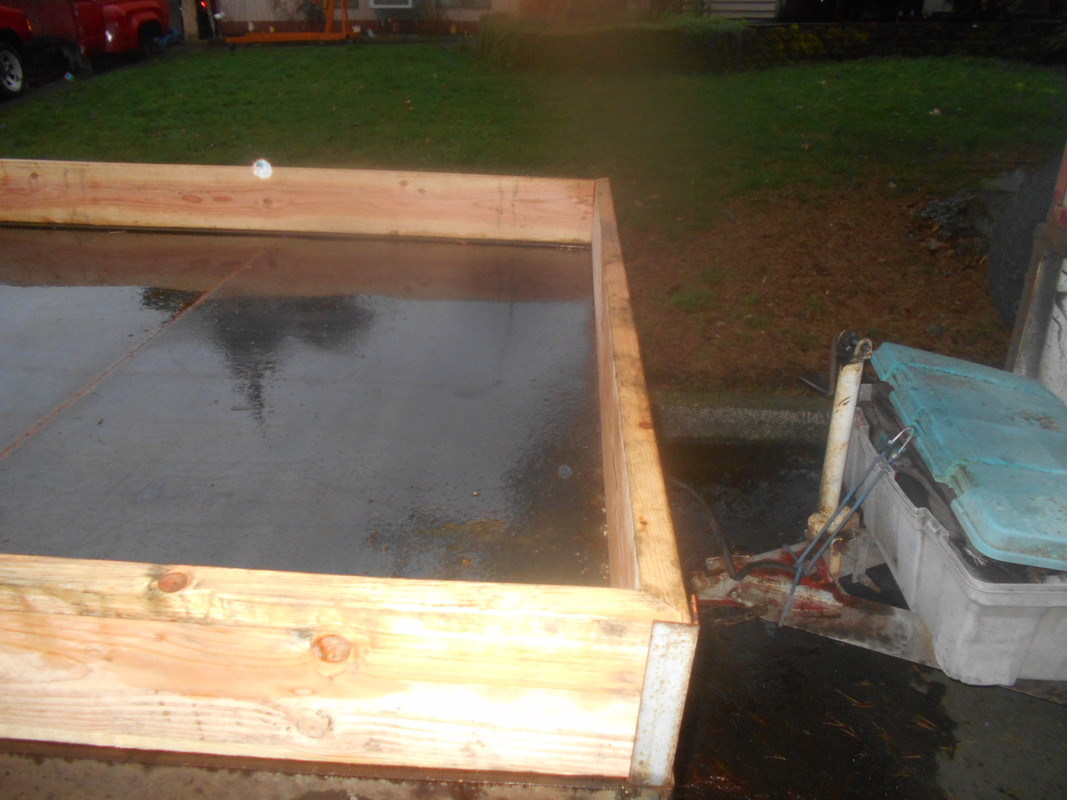

Today I removed the flatbed outer frame from the 521 chassis, as I cut it out I realized it was on the verge of rotting out, the 1 inch square tubing that the 2X6 boards rested on were bent and half rusted, I can hardly believe the last couple loads didn't collapse it, it came apart pretty easy, I lifted it off the chassis and rolled the chassis out from under it and then I backed the truck half under it and then slid it on the dump frame beams.

I then removed the tow hitch, I removed all the 8 bolts holding it on and then realized that it had almost fallen off, as the frame had fell apart when I towed the trailer one time, so I had repaired the frame and then bolted the hitch on, then I welded it to the frame also, it never moved after that, and it took a little time to get it off, what I did was grind off welds and hit it with a sledge, repeat, repeat till it moved, I then installed it on this chassis, I cut a lot of things today, but that is basically what got done.

It appears I will have to shorten the flatbed as it is too long by around 4 inches, I need to look at it some more, I would rather not shorten it unless I have to, but the tow hitch ball is not sticking out very far.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Today I got a lot of the flatbed done, I shortened the flatbed 7 inches, I have most the cross stringers placed and the sheet metal flatbed part has been cut and half of it installed, I will try to finish the setup tomorrow, but once all in position there is a lot of welding to do.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

So today I for the most part finished the flatbed itself, I need to buy and make the side boards to use it.

Tomorrow I will see about the wiring for the rear lights, I pretty much tried to disassemble that by unplugging or unscrewing the grounds, I tried not to cut anything, so it should for the most part be plug it in and drive it except for the grounds which I will have to drill holes and mount the ground wires.

I forgot I also have to redo the back end look as I had to cut where the license plate was mounted out as that was hitting the trailer hitch package when I lifted the bed.

I also had an issue with the relay that operates the lift bed, for some reason that is shorting out now, not sure I can even buy that part anymore, I could lift the bed by bypassing it, but it is not as easy to use that way, I will figure something out.

Tomorrow I will see about the wiring for the rear lights, I pretty much tried to disassemble that by unplugging or unscrewing the grounds, I tried not to cut anything, so it should for the most part be plug it in and drive it except for the grounds which I will have to drill holes and mount the ground wires.

I forgot I also have to redo the back end look as I had to cut where the license plate was mounted out as that was hitting the trailer hitch package when I lifted the bed.

I also had an issue with the relay that operates the lift bed, for some reason that is shorting out now, not sure I can even buy that part anymore, I could lift the bed by bypassing it, but it is not as easy to use that way, I will figure something out.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

I started today by cutting off the piece of metal I added below the the 2X6 steel back flatbed frame piece that holds the taillights, it was hitting my tow hitch and it looked ugly by the time it didn't touch from cutting off what was hitting, I then remounted my license plate to the side 4 inches so it was still under the light but didn't hit the tow hitch.

Next I wired the taillights, this took a while as they were not working properly, I kept looking for a missing ground wire(couple hours) and it finally occurred to me that maybe even though the dump flatbed was connected by two pivot points that maybe it was not grounding properly, I mounted an extra wire on the license plate light ground screw and then connected it to the frame/chassis and all was good.

Next I wired the electric brakes wire, it took around 4 hours to complete all the stuff so far, I took a break for a couple hours.

Next I wired the fuel pump to a keyed source, then I cut a new hole in my tunnel plate for the shift lever and filled the old shift lever hole, as I am now using a long shaft transmission, the shift lever is 5 inches closer to me now which is going to be awesome, at least I hope I like it.

Next I started on mounting the shift lever console, I have it where I want it, but to finish it I will need to remove the bench seat as I cannot get to the rear mount screws as it is jammed against the seat, the seat adjustment lever is also hitting it, not sure what I am going to do about that yet.

I really cannot mount the console before putting the carpet in, but I do have leaks on both sides, I was going to figure that out when I install the 720 wiring harness, but I will likely just put the carpet in so I can keep moving forward.

Next I wired the taillights, this took a while as they were not working properly, I kept looking for a missing ground wire(couple hours) and it finally occurred to me that maybe even though the dump flatbed was connected by two pivot points that maybe it was not grounding properly, I mounted an extra wire on the license plate light ground screw and then connected it to the frame/chassis and all was good.

Next I wired the electric brakes wire, it took around 4 hours to complete all the stuff so far, I took a break for a couple hours.

Next I wired the fuel pump to a keyed source, then I cut a new hole in my tunnel plate for the shift lever and filled the old shift lever hole, as I am now using a long shaft transmission, the shift lever is 5 inches closer to me now which is going to be awesome, at least I hope I like it.

Next I started on mounting the shift lever console, I have it where I want it, but to finish it I will need to remove the bench seat as I cannot get to the rear mount screws as it is jammed against the seat, the seat adjustment lever is also hitting it, not sure what I am going to do about that yet.

I really cannot mount the console before putting the carpet in, but I do have leaks on both sides, I was going to figure that out when I install the 720 wiring harness, but I will likely just put the carpet in so I can keep moving forward.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Waynos work truck.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Today I did a few things, I started with the carpet, console, and seat, I cut the holes needed for the carpet, it is in, then I put a kingcab console with the gauges transferred into it, connected everything and it all works, I then turned the seat over and unscrewed the adjustment lever and zip tied it to a couple of the seat springs complete, I never plan to move it forward and the console is in the way anyway.

Here is a photo of the console and the shift lever in reverse which is the closest it gets to the seat, you can see the console is against the seat bottom.

After I finished the interior stuff I moved to the lift bed relay that was shorting out, I got it out of there, it is not an electrical relay in the sense that you flip a switch in the truck and the bed lifts, that is actually supposed to be done with a lever that controls both up and down, up is electric, down is releasing the pressure in the cylinders, both are mechanically controlled with a lever, well I opened the relay up to see why it was shorting out and figured that out right away, the spring inside was wasted/rusted away, and the battery side post had lost half of it insulation, the post was resting on the housing it is bolted in, it took me a while to get it to work properly, I used 1/8th inch thick Mr Gasket material for the inside and the outside I used what was already there, I put it back together and keep in mind that this part lid is formed to fit and I had to peel it back to get it off, then I had to tap all the way around to put it back to the original shape to put it back together, twice I did this, the second time I pulled it all the way apart and cleaned everything, it works great now, again it is an electric relay that is manually operated.

I also had to tighten up all the linkage to get it to work in the both the up and down modes using the lever where it ends right now, I have work tomorrow if it doesn't rain, so next I will either fab up a lever for the cab, or more than likely I will make a lever under the driver side bed front corner to control it from the outside all though others could operate it when I am not there, but I suppose I could use the relay I was using to start it to control when the tilt bed has power from inside the cab, the relay is already mounted and I installed/routed an old set of jumper cables(both sides) to supply power to the tilt bed motor, safety wise I should wire in a power relay, all I would need to do is move the cables to the relay, put a cable from the starter post to the relay, and then wire in a switch, easy to do.

The last thing I did was drive it to the gas station and I filled it up, totally full the gauge only shows just over half a tank, so either the float arm gets jammed just over half way up because of rust/oxidation, or it is not functioning properly as when I grounded the wire it showed full tank, then I drove to Home Depot and bought four 8 foot 2X8s for the sides/front back like I had on the old bed, not sure how I am going to do it yet as I want the sides to stay in position when I remove the back piece when I dump the load, but I also don't want anything hanging out and getting ripped off when I do dump the load, but I want the sides removable also, I will figure something out.

On the test drive I realized the exhaust is touching the cab, I will have to cut the tile pipe off where it makes the turn to the side at the back, let the system hang free like it is supposed to and then weld the part I cut off at a better angle, it was fine till I installed the tow package, so I tried to make it work without cutting anything but failed.

Here is a photo of the console and the shift lever in reverse which is the closest it gets to the seat, you can see the console is against the seat bottom.

After I finished the interior stuff I moved to the lift bed relay that was shorting out, I got it out of there, it is not an electrical relay in the sense that you flip a switch in the truck and the bed lifts, that is actually supposed to be done with a lever that controls both up and down, up is electric, down is releasing the pressure in the cylinders, both are mechanically controlled with a lever, well I opened the relay up to see why it was shorting out and figured that out right away, the spring inside was wasted/rusted away, and the battery side post had lost half of it insulation, the post was resting on the housing it is bolted in, it took me a while to get it to work properly, I used 1/8th inch thick Mr Gasket material for the inside and the outside I used what was already there, I put it back together and keep in mind that this part lid is formed to fit and I had to peel it back to get it off, then I had to tap all the way around to put it back to the original shape to put it back together, twice I did this, the second time I pulled it all the way apart and cleaned everything, it works great now, again it is an electric relay that is manually operated.

I also had to tighten up all the linkage to get it to work in the both the up and down modes using the lever where it ends right now, I have work tomorrow if it doesn't rain, so next I will either fab up a lever for the cab, or more than likely I will make a lever under the driver side bed front corner to control it from the outside all though others could operate it when I am not there, but I suppose I could use the relay I was using to start it to control when the tilt bed has power from inside the cab, the relay is already mounted and I installed/routed an old set of jumper cables(both sides) to supply power to the tilt bed motor, safety wise I should wire in a power relay, all I would need to do is move the cables to the relay, put a cable from the starter post to the relay, and then wire in a switch, easy to do.

The last thing I did was drive it to the gas station and I filled it up, totally full the gauge only shows just over half a tank, so either the float arm gets jammed just over half way up because of rust/oxidation, or it is not functioning properly as when I grounded the wire it showed full tank, then I drove to Home Depot and bought four 8 foot 2X8s for the sides/front back like I had on the old bed, not sure how I am going to do it yet as I want the sides to stay in position when I remove the back piece when I dump the load, but I also don't want anything hanging out and getting ripped off when I do dump the load, but I want the sides removable also, I will figure something out.

On the test drive I realized the exhaust is touching the cab, I will have to cut the tile pipe off where it makes the turn to the side at the back, let the system hang free like it is supposed to and then weld the part I cut off at a better angle, it was fine till I installed the tow package, so I tried to make it work without cutting anything but failed.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Today after my jobs I cut the tail pipe and welded it back on at a different angle, I have not driven it yet.

I also made the bed rails out of the 2X8s, I basically did the exact same thing I had before, but this time I will bolt the boards to the front angle iron stakes, this will keep them from moving/sliding backwards when I use the dump bed, the back ends of the side rails are cut at a 45 degree angle along with both ends of the back rail, so the angle iron stake holds them both together at the back corner, I am considering holding the front rail onto the front rack with metal straps screwed into the board around the rack uprights, I will take a photo of all this tomorrow.

I also made the bed rails out of the 2X8s, I basically did the exact same thing I had before, but this time I will bolt the boards to the front angle iron stakes, this will keep them from moving/sliding backwards when I use the dump bed, the back ends of the side rails are cut at a 45 degree angle along with both ends of the back rail, so the angle iron stake holds them both together at the back corner, I am considering holding the front rail onto the front rack with metal straps screwed into the board around the rack uprights, I will take a photo of all this tomorrow.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

I got close to finishing this truck today, I finished the bed rails, I did exactly what I said, I bolted the side rails to the front stake.

The backs are cut at a 45 degree angle but not attached to the rear stake.

Here is how it is sitting right now, I need to loosen the front torsion bars even more than I already did today, I loosened them a half inch already at the bolts, need to go another half inch but it started raining so i came inside.

Not sure if it can be seen, but the front board is bolted to the left upright in this photo below, the right side is held by the lift in the bed.

I also connected the trailer to the truck as you can see in the first photo, when I went to connect the trailer plug to the receptacle on the truck it would not reach, so I had to make some mods to the wiring harness and I will need to make a new mount, I drove it with the trailer and the brakes work way better on this truck the way it is now than the way it was, that is worth all this effort alone, the steering is super tight also but I had fixed that pretty good the last time it fell apart last fall.

Yesterday I tightened all the bolts holding this dump bed package and I added 4 bolts, well the bed would not go up all the way today till I loosened the 2 rear mount bolts I added, it still has 3 bolts on each side, not sure what I am going to do yet.

Another thing that has happened is the passenger side hydraulic cylinder is leaking fluid when I stop raising the bed, I might need to buy at least one cylinder, maybe 2 of them depending on the price.

Oh, I also made a little lever to control the bed where it is easy to get to, the first photo is of the original lever connection that goes to the original lever in the cab which the 86 cab didn't have, the second photo is of the lever I welded to one of the activation levers.

The backs are cut at a 45 degree angle but not attached to the rear stake.

Here is how it is sitting right now, I need to loosen the front torsion bars even more than I already did today, I loosened them a half inch already at the bolts, need to go another half inch but it started raining so i came inside.

Not sure if it can be seen, but the front board is bolted to the left upright in this photo below, the right side is held by the lift in the bed.

I also connected the trailer to the truck as you can see in the first photo, when I went to connect the trailer plug to the receptacle on the truck it would not reach, so I had to make some mods to the wiring harness and I will need to make a new mount, I drove it with the trailer and the brakes work way better on this truck the way it is now than the way it was, that is worth all this effort alone, the steering is super tight also but I had fixed that pretty good the last time it fell apart last fall.

Yesterday I tightened all the bolts holding this dump bed package and I added 4 bolts, well the bed would not go up all the way today till I loosened the 2 rear mount bolts I added, it still has 3 bolts on each side, not sure what I am going to do yet.

Another thing that has happened is the passenger side hydraulic cylinder is leaking fluid when I stop raising the bed, I might need to buy at least one cylinder, maybe 2 of them depending on the price.

Oh, I also made a little lever to control the bed where it is easy to get to, the first photo is of the original lever connection that goes to the original lever in the cab which the 86 cab didn't have, the second photo is of the lever I welded to one of the activation levers.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Waynos work truck.

Put it to work!

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

I put a cover over the seat before it gets worse, should be good for a long time now.

I also made the new mount for the trailer plug receptacle.

I did some other stuff also, I loosened the torsion bars another half inch, it doesn't appear to be making much of a difference in the front height, it had a Z24 engine, now it has a LZ23, it cannot be that much lighter.

For now I am going to leave the 4.6 geared axle in it, see if it drives me crazy, it sure starts out easier than it did with the 4.3 gearing, but the truck is empty also, I will try it out for a while, I also am going to use this wiring harness for a while, if things keep working properly I will live with the 521 harness for a while as i am tired of working on it, I need a break.

I need to do some cleaning up around here.

I also made the new mount for the trailer plug receptacle.

I did some other stuff also, I loosened the torsion bars another half inch, it doesn't appear to be making much of a difference in the front height, it had a Z24 engine, now it has a LZ23, it cannot be that much lighter.

For now I am going to leave the 4.6 geared axle in it, see if it drives me crazy, it sure starts out easier than it did with the 4.3 gearing, but the truck is empty also, I will try it out for a while, I also am going to use this wiring harness for a while, if things keep working properly I will live with the 521 harness for a while as i am tired of working on it, I need a break.

I need to do some cleaning up around here.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Waynos work truck.

Those seat covers are indestructable. Yours looks identical to the one in my Smell Camino.

Take a break for a while. You've earned it.

Take a break for a while. You've earned it.

When the only tool you have is a hammer every problem starts to look like a hippy.

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

I started tearing into the old frame taking it apart piece by piece, I looked down and seen a rust hole in the side of the frame right behind where it had been extended, I turned around and the other side was the same, I looked forward of the extension and one side was bad there also, so I scratched the idea that someone might want this frame and started cutting it up.

When I got to the front control arms after I removed the brake assemblies I realized the lower control arm bushings were wasted, one side is so bad that I suspect the inner sleeve is not even connected to the rubber anymore but it could not fall out as there wee to many other things holding it there like the torsion bar and large washers on the front along with the control arm being on both sides also, no wonder the steering has been so loose, also the tension rod bushings were shot, the front end was so loose that I am surprised I didn't go thru tires every month.

It was time to do this conversion even though I didn't know it was time.

When I got to the front control arms after I removed the brake assemblies I realized the lower control arm bushings were wasted, one side is so bad that I suspect the inner sleeve is not even connected to the rubber anymore but it could not fall out as there wee to many other things holding it there like the torsion bar and large washers on the front along with the control arm being on both sides also, no wonder the steering has been so loose, also the tension rod bushings were shot, the front end was so loose that I am surprised I didn't go thru tires every month.

It was time to do this conversion even though I didn't know it was time.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Well I finished cutting this 521 frame apart, I was right about how bad the LCA bushings were, they were not even connected.

This chassis/frame was falling apart, it was just a matter of time before a catastrophic failure occurred, rust holes in the frame, bushings wasted, frame falling apart every couple years where the power steering gear was mounted, it was time, when others say it was time they scrap the vehicle or sell it, I just keep making larger fixes.

This chassis/frame was falling apart, it was just a matter of time before a catastrophic failure occurred, rust holes in the frame, bushings wasted, frame falling apart every couple years where the power steering gear was mounted, it was time, when others say it was time they scrap the vehicle or sell it, I just keep making larger fixes.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

Well I drove this truck today, it doesn't have a quality ride at all, I expect I will have to put my 521 rear leaf packs and coil over shocks on this setup to get my ride back, I don't know if these leafs are firmer, but the ride sucks when it was fairly smooth before.

I also can feel the weight that was not there before, even though this one has 4.625 gears it starts out slower than it did when it had 4.37 gears, it just weighs more with the dump bed.

The speedo is right on now, it used to show faster than I was really going, but when I went past the radar signs today it was right on.

It is a lot quieter now than it has been for several years.

It also has an issue now, the SU bowls are getting hot now and it is not even hot outside, I am not using the return right now, I will have to plumb a return as it is missing real bad after I sit at a stop light but smooths out once I get air flowing thru the radiator/engine compartment, I need to figure out how I am going to control the fuel pressure.

I also can feel the weight that was not there before, even though this one has 4.625 gears it starts out slower than it did when it had 4.37 gears, it just weighs more with the dump bed.

The speedo is right on now, it used to show faster than I was really going, but when I went past the radar signs today it was right on.

It is a lot quieter now than it has been for several years.

It also has an issue now, the SU bowls are getting hot now and it is not even hot outside, I am not using the return right now, I will have to plumb a return as it is missing real bad after I sit at a stop light but smooths out once I get air flowing thru the radiator/engine compartment, I need to figure out how I am going to control the fuel pressure.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

So I made the holder under the driver side bed for this box I have had for over 20 years, it has my jack, lug wrench and gutter downspout screens I have in case I pressure wash a roof and they don't have screens, I don't want anyone telling me I plugged their underground system up with moss from the roof.

I also have mentioned having issues with my fuel getting hot as I was not using a return line, well I piped the return into the system, what I did for a regulator was weld up an end on a "Tee", then I drilled a 1/16th inch hole in the end I welded up, that connects to the return hose, I am hoping that hole isn't too big, therefore not allowing the system to build up enough pressure, I make this shit up as i go, if I have to I can bypass the regulator if I have issues and try again later, the issue is it is not even hot out and I am having fuel heat issues.

I also have mentioned having issues with my fuel getting hot as I was not using a return line, well I piped the return into the system, what I did for a regulator was weld up an end on a "Tee", then I drilled a 1/16th inch hole in the end I welded up, that connects to the return hose, I am hoping that hole isn't too big, therefore not allowing the system to build up enough pressure, I make this shit up as i go, if I have to I can bypass the regulator if I have issues and try again later, the issue is it is not even hot out and I am having fuel heat issues.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein

- wayno

- Posts: 5320

- Joined: Thu Jun 27, 2013 8:44 pm

- Location: Vancouver WA

- Has thanked: 432 times

- Been thanked: 1302 times

Re: Waynos work truck.

So today I decided to get rid of all the automobile scrap metal I have around here, I loaded the truck up with all the cut up sheet metal I have collected over the years along with the 521 chassis/frame pieces and the cut up 1986 720 cab, I got turned away at 2 scrap metal yards(they wanted titles), I called a hulk hauler guy I know and asked him if I could come over and ask him what I needed to do to get rid of this load, I drove to his house and he seemed surprised that I wasn't able to get rid of it as cut up as it was, he told me to go to this place I will not name, but in the end he took it off my hands as I offered him money to take it, he took it but would not take my money, I will leave him some good scrap in the future outside his gate where it says to leave scrap.

I will never do that again, I am done with collecting scrap metal as it is too hard to sell if automotive related, I am so happy that stuff is gone, I likely had close to a half ton in the flatbed, it drove way nicer with the weight back there.

I started another box on the passenger side in front of the back wheels, this one will open without having to raise the bed, it will also likely have the gas filler inside it or maybe I will notch the door in the upper left corner and have the filler cap on the outside, I have not decided yet, I was also thinking about putting the battery in this box, or another battery to power the dump bed and have it isolated from the main battery but have a relay that charges it whenever the engine is running.

My alternator is starting to act weird, I have to rev it pretty high before it starts charging, and the ign light id just barely on all the time, but it show charging at least 14 volts when it kicks in.

I will never do that again, I am done with collecting scrap metal as it is too hard to sell if automotive related, I am so happy that stuff is gone, I likely had close to a half ton in the flatbed, it drove way nicer with the weight back there.

I started another box on the passenger side in front of the back wheels, this one will open without having to raise the bed, it will also likely have the gas filler inside it or maybe I will notch the door in the upper left corner and have the filler cap on the outside, I have not decided yet, I was also thinking about putting the battery in this box, or another battery to power the dump bed and have it isolated from the main battery but have a relay that charges it whenever the engine is running.

My alternator is starting to act weird, I have to rev it pretty high before it starts charging, and the ign light id just barely on all the time, but it show charging at least 14 volts when it kicks in.

“The difference between genius and stupidly is that genius has its limits” Albert Einstein