Jacob's goon build

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

I do, but I have ran over everyone I have set... So... But I did pay of the BMW, so extra funds...

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

Updates... and Maybe Ill have more tomorrow!

Parts came in...

3" (Stretched to 3.125") to 2.5" reducer. That is a 300zx MAF.

A 2" to 2.5" offset reducer, this is the hotside pipe to intercooler adapter

A 2" hump coupler, Turbo outlet

New 3/4-16 LH weld bungs for the LCAs

New QA1 linkage adjuster (Female 3/4-16 RH to Male 3/4-16 LH)

Turbo lookin pretty; I really need to make the exhaust manifold look nicer...

Hot side pipe done. Not sure why (Cant find legit info), but almost every build and all OEMs use a smaller side hot side pipe. So this is the same as the turbo outlet, 2". The pipe is not touching anything it has about 3/4" space all all around it. (Yes I know those are the wrong clamps. I have the right ones on order. These are temporary and not very tight.)

Here is my modified laser line (I opened it and desoldered the vacuum pump motor to save battery and reduce noise), it is broadcasting a laser line (better visible in the next pic).

Close up of the laser line. Using it to line up the Weld bung to the ball joint (something I didnt do on my first versions of the LCAs).

I have both LCAs cut/welded. Now I need to do the T/C rods. Been trying to figure out the cold side intake piping, as well as the radiator hoses (real close, may have pictures soon).

Parts came in...

3" (Stretched to 3.125") to 2.5" reducer. That is a 300zx MAF.

A 2" to 2.5" offset reducer, this is the hotside pipe to intercooler adapter

A 2" hump coupler, Turbo outlet

New 3/4-16 LH weld bungs for the LCAs

New QA1 linkage adjuster (Female 3/4-16 RH to Male 3/4-16 LH)

Turbo lookin pretty; I really need to make the exhaust manifold look nicer...

Hot side pipe done. Not sure why (Cant find legit info), but almost every build and all OEMs use a smaller side hot side pipe. So this is the same as the turbo outlet, 2". The pipe is not touching anything it has about 3/4" space all all around it. (Yes I know those are the wrong clamps. I have the right ones on order. These are temporary and not very tight.)

Here is my modified laser line (I opened it and desoldered the vacuum pump motor to save battery and reduce noise), it is broadcasting a laser line (better visible in the next pic).

Close up of the laser line. Using it to line up the Weld bung to the ball joint (something I didnt do on my first versions of the LCAs).

I have both LCAs cut/welded. Now I need to do the T/C rods. Been trying to figure out the cold side intake piping, as well as the radiator hoses (real close, may have pictures soon).

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

No real update... (as in no pics).

First of all, that aluminum thing you see in the background of a few of my pics (like the 2 above), is amazing. Its a quick platform. 20" tall, 18" wide, 36" long. It folds. Its sturdy. It also makes for a awesome welding table. I can just put my ground clamp anywhere on it, and start welding. Its super versatile, and it hides easily. It was a Christmas present, but I have seen them around for not too much.

Today was a bit uneventful. I woke up late. Then had my sisters birthday dinner (oh sooo yummy, that place should be a 5 star restaurant). Then went out for some drinks. I did manage to squeeze a few thing in today though.

Started roughing in the lower radiator hose, stainless sucks, Im buying a bandsaw tomorrow.

Swapped the alternator pulley from a V belt one to a serpentine one (back to original, I put the V belt one on for the L series).

And then I installed the actuator for the passenger rear door for the lock/unlock feature (I for some reason did all the other doors, just not that one...)

First of all, that aluminum thing you see in the background of a few of my pics (like the 2 above), is amazing. Its a quick platform. 20" tall, 18" wide, 36" long. It folds. Its sturdy. It also makes for a awesome welding table. I can just put my ground clamp anywhere on it, and start welding. Its super versatile, and it hides easily. It was a Christmas present, but I have seen them around for not too much.

Today was a bit uneventful. I woke up late. Then had my sisters birthday dinner (oh sooo yummy, that place should be a 5 star restaurant). Then went out for some drinks. I did manage to squeeze a few thing in today though.

Started roughing in the lower radiator hose, stainless sucks, Im buying a bandsaw tomorrow.

Swapped the alternator pulley from a V belt one to a serpentine one (back to original, I put the V belt one on for the L series).

And then I installed the actuator for the passenger rear door for the lock/unlock feature (I for some reason did all the other doors, just not that one...)

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Jacob's goon build

Keep at it. That's how projects get finished. (Like I'd know  )

)

When the only tool you have is a hammer every problem starts to look like a hippy.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

Should have gone to bed sooner, but new toys meant I had to do something.

Got the Lower radiator pipe all lined up. Just gonna prep it for welding and have the welder at work do it. Then once its back, I will have to get a port welded to this...

Got the Lower radiator pipe all lined up. Just gonna prep it for welding and have the welder at work do it. Then once its back, I will have to get a port welded to this...

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

Boom!

Had a bead welded on either end for a mechanical lock.

I did do something else minor... Probably show it this weekend when it gets used.

Had a bead welded on either end for a mechanical lock.

I did do something else minor... Probably show it this weekend when it gets used.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Jacob's goon build

Nice

When the only tool you have is a hammer every problem starts to look like a hippy.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

So awhile back I got discouraged at the price of T-bolt clamps. They are stupid expensive, and then if you want full stainless ones, that will be even more money. And they you have to multiply that by the number of clamps you need. So there has to be an alternative. I reinforced my idea from this Article. (AMS makes the infamous GTR drag car, as of this year its pushing 2800+hp and 2000+tq).

Found these sweet HPS worm clamps. They are embossed stainless, so no sharp edges, from a company who makes super nice silicone pieces (Im using them exclusively) and are relatively cheap. Less T-bolt clamp price, more expensive worm clamp price.

Besides that, I started on the TC pockets. This one is "done." Im actually gonna work it over a bit more and reduce some of the weight. I turned those adapters next to the heim joints out of stainless. I spent some time planning this out...

Note, the bolts used for mockup are not final. I am going to run Grade 8, and find the best suited bolt possible.

Found these sweet HPS worm clamps. They are embossed stainless, so no sharp edges, from a company who makes super nice silicone pieces (Im using them exclusively) and are relatively cheap. Less T-bolt clamp price, more expensive worm clamp price.

Besides that, I started on the TC pockets. This one is "done." Im actually gonna work it over a bit more and reduce some of the weight. I turned those adapters next to the heim joints out of stainless. I spent some time planning this out...

Note, the bolts used for mockup are not final. I am going to run Grade 8, and find the best suited bolt possible.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

After the BMW fix I had mothers day stuff to do. Then more drinks (its still the weekend...). Got home and decided I really needed to do something on the 510.

I had already tacked the TC pocket onto the frame where I thought it should go (that laser level sure is handy). So then I needed to make the bracket on the LCA.

So I turned Cardboard into metal:

Ill get the upper piece done tomorrow hopefully before work (My shift just got moved 2 hours ahead, so maybe not...)

I had already tacked the TC pocket onto the frame where I thought it should go (that laser level sure is handy). So then I needed to make the bracket on the LCA.

So I turned Cardboard into metal:

Ill get the upper piece done tomorrow hopefully before work (My shift just got moved 2 hours ahead, so maybe not...)

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Jacob's goon build

When the only tool you have is a hammer every problem starts to look like a hippy.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

I did in fact get to make the other piece before work, but ran out of time to update earlier.

When I got home I decided to cycle the suspension the full range with the steering locked. Made a jig to show the laser on the wall. Im happy.

More cardboard to metal magic:

Jig shot, suspension is fully collapsed. (Cant actually do that on the car, the tire hits the upper frame rail).

Fully dropped as far as the suspension wants to go. I actually think its the LCA bushing restricting it as it should be able to move freely, course the TC rod has more limited movement... Anyways, I measure the height change, 8 inches. The laser deflected less than 1/8th inch up and down, so little that Im not even going to do the math to figure out the angle change.

When I got home I decided to cycle the suspension the full range with the steering locked. Made a jig to show the laser on the wall. Im happy.

More cardboard to metal magic:

Jig shot, suspension is fully collapsed. (Cant actually do that on the car, the tire hits the upper frame rail).

Fully dropped as far as the suspension wants to go. I actually think its the LCA bushing restricting it as it should be able to move freely, course the TC rod has more limited movement... Anyways, I measure the height change, 8 inches. The laser deflected less than 1/8th inch up and down, so little that Im not even going to do the math to figure out the angle change.

- RedBanner

- Posts: 2626

- Joined: Wed Jun 26, 2013 6:48 pm

- Title: MasterBlaster

- Location: vancouver , wa

- Has thanked: 2 times

- Been thanked: 2 times

- Contact:

Re: Jacob's goon build

Wow man, I'm coveting...

wayno » Sat Jul 12, 2014 9:40 pm wrote: Everything is either tight or actually rubbing.

Taterhead » Tue Aug 05, 2014 2:29 pm wrote:Datsun gods will give you one working gauge, gasoline or speedometer; you can't have both.

- Taterhead

- Posts: 2493

- Joined: Thu Jul 11, 2013 4:18 am

- Cars: '71 510 - Mine

'72 510 - Sons - Location: Central Alabama

- Has thanked: 1354 times

- Been thanked: 236 times

- Converted_to_datsun

- Posts: 458

- Joined: Fri Jun 28, 2013 3:33 pm

- Cars: 74 Datsun b210, 94 Nissan hard body sas, 07 Ford Focus

- Been thanked: 1 time

Re: Jacob's goon build

I've gotta get one of those laser levels.... looks great! I'm mainly jealous of your garage tho hahaha

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

Thanks guys.

I was really trying to get more done this weekend, but other projects (like roommates motorcycle).

Pulled the TC pocket on the drivers side, the one I attached as a replacement. Um, plug welds, they were not going to come undone, they were horrendous to grind out. At least it makes me more confident in my welding.

Driver side TC pocket with Speed holes!:

LCA side TC rod attachment, driver side:

The metal bits to make this:

Also got new Sway Bar bushing in. Endlinks are in the mail. These bushings are cool. They are Poly with a PTFE fibrous lining. Supposedly grease free:

I was really trying to get more done this weekend, but other projects (like roommates motorcycle).

Pulled the TC pocket on the drivers side, the one I attached as a replacement. Um, plug welds, they were not going to come undone, they were horrendous to grind out. At least it makes me more confident in my welding.

Driver side TC pocket with Speed holes!:

LCA side TC rod attachment, driver side:

The metal bits to make this:

Also got new Sway Bar bushing in. Endlinks are in the mail. These bushings are cool. They are Poly with a PTFE fibrous lining. Supposedly grease free:

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

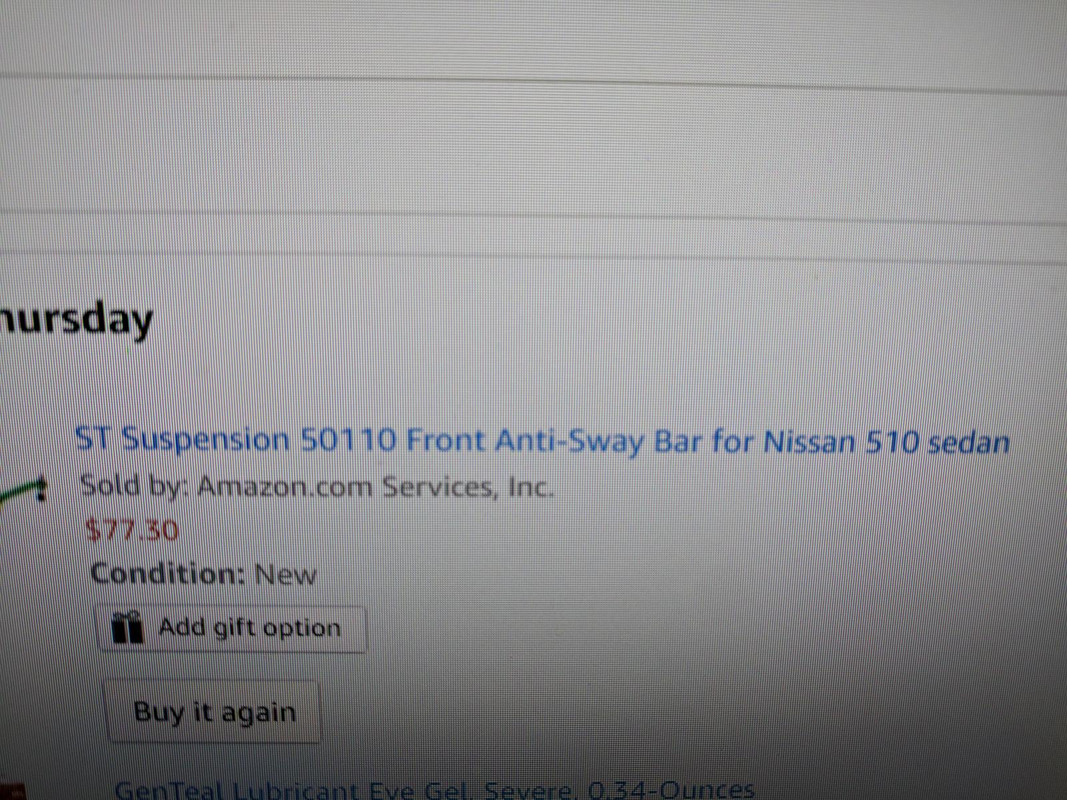

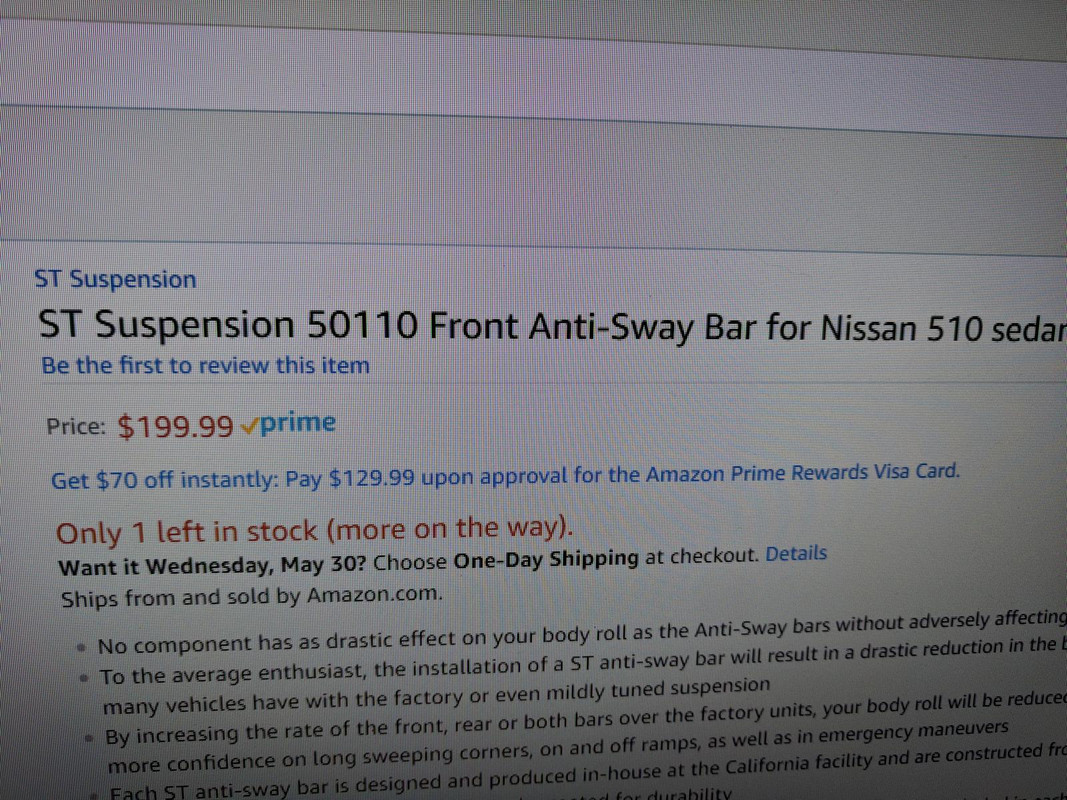

So doing things on the 510. Looking at the 1" sway bar I have and intending to use, it's bent and twisted.

Well shit, no point in doing mock-up with a bent sway bar.

Go online, hunting for a deal. Check all the usual places, finally find one for $160 from a reputable source. Still not happy with the price. Decide to change up my search query and I pull up an Amazon link. add to cart, buy! I scored.

add to cart, buy! I scored.

This is how much I got it for.

I know this is an Amazon pricing error, they do this thing if a product doesn't sell for awhile, they drop the price alot. After someone buys one they up the price, often back to full price. So I checked after I got my order confirmation.

Well shit, no point in doing mock-up with a bent sway bar.

Go online, hunting for a deal. Check all the usual places, finally find one for $160 from a reputable source. Still not happy with the price. Decide to change up my search query and I pull up an Amazon link.

This is how much I got it for.

I know this is an Amazon pricing error, they do this thing if a product doesn't sell for awhile, they drop the price alot. After someone buys one they up the price, often back to full price. So I checked after I got my order confirmation.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Jacob's goon build

Have you tried working that bent one in a hydraulic press to see if it can be persuaded back to where it started?

When the only tool you have is a hammer every problem starts to look like a hippy.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

If it was just bent, maybe, but it's also twisted. And the bent sections are right at or next to the bends making it hard to press in the correct direction. It keeps wanting to roll.

- DRIVEN

- Posts: 7699

- Joined: Thu Jun 27, 2013 7:05 pm

- Location: I've been everywhere

- Has thanked: 1210 times

- Been thanked: 1180 times

Re: Jacob's goon build

Gotcha.

Carry on.

Carry on.

When the only tool you have is a hammer every problem starts to look like a hippy.

- Laecaon

- Site Admin

- Posts: 4793

- Joined: Wed Jun 26, 2013 7:21 pm

- Cars: '71 510 Wagon, 02 BMW 325i Wagon

- Location: PDX, West side.

- Has thanked: 288 times

- Been thanked: 329 times

Re: Jacob's goon build

Figure I should try and add something here.

Had to order this from McMaster, its a 1/8 BPST to -4an (or actually a JIC fitting in this case.)

Found some sway bar end links I can use. These are from the rear of a early 90s Eclipse.

Here you can see it all in action. About here is where I discovered my sway bar is bent. Pretty sure I cycled the suspension and it all clears somehow...

Grabbed some of these Metric M14x1.5 to -6an fittings...

Cleaned out the threads on the water jacket of the Turbo (and a coolant port on the block).

This is the Coolant port to feed the Turbo with a fitting in it.

Turbo got the fittings too, one on each side for entry and exit.

I was really hoping to be posting other stuff...

Had to order this from McMaster, its a 1/8 BPST to -4an (or actually a JIC fitting in this case.)

Found some sway bar end links I can use. These are from the rear of a early 90s Eclipse.

Here you can see it all in action. About here is where I discovered my sway bar is bent. Pretty sure I cycled the suspension and it all clears somehow...

Grabbed some of these Metric M14x1.5 to -6an fittings...

Cleaned out the threads on the water jacket of the Turbo (and a coolant port on the block).

This is the Coolant port to feed the Turbo with a fitting in it.

Turbo got the fittings too, one on each side for entry and exit.

I was really hoping to be posting other stuff...